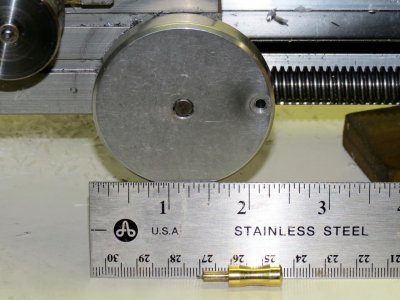

The brass press-on handle on my Taig Carriage Wheel has worked itself loose (see how I blame the machine for breaking itself!)

I see my options as

1) replace - not very "machinist" approach;

2) Loc-Tite - see above;

3) Drill and tap for a brass bolt to hold a spinning handle. (I am thinking bolt through a brass spinner, then lock nut, then into a tapped wheel.)

(What is the difference between a bolt and a machine screw?)

Does anyone have any recommendations for size, etc. (bolt diameter and length, handle length/diameter) or another option I haven't thought of?

Thanks!

I see my options as

1) replace - not very "machinist" approach;

2) Loc-Tite - see above;

3) Drill and tap for a brass bolt to hold a spinning handle. (I am thinking bolt through a brass spinner, then lock nut, then into a tapped wheel.)

(What is the difference between a bolt and a machine screw?)

Does anyone have any recommendations for size, etc. (bolt diameter and length, handle length/diameter) or another option I haven't thought of?

Thanks!