- Joined

- Jun 17, 2011

- Messages

- 2,062

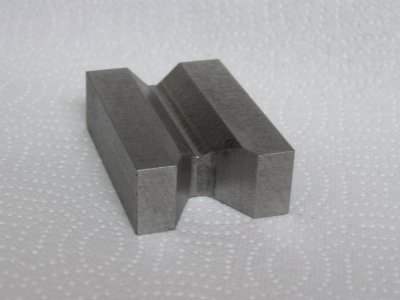

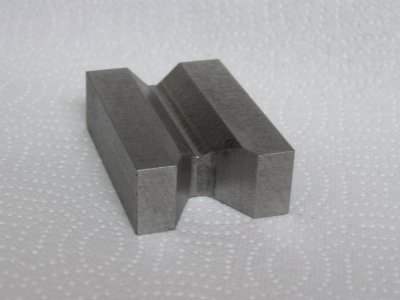

I wanted a project to do on the shaper and had just picked up a bar of cast unknownium, so this seemed a natural choice. Now I know you can buy new ones for $20, but having one isn't the point. I'll start with a shot I posted on another thread a short time ago - the rough block of cast.

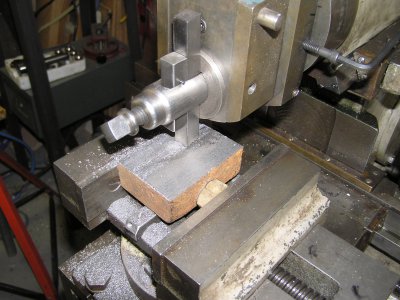

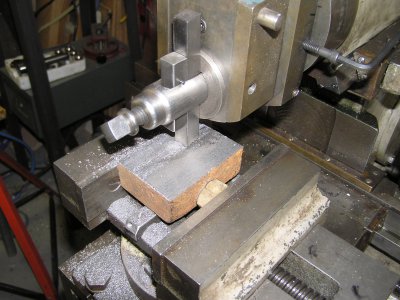

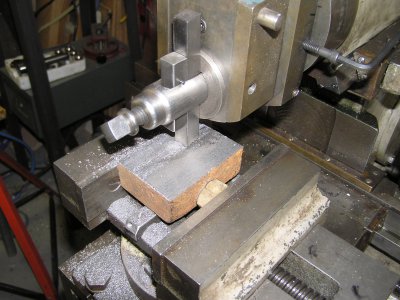

Cleaning up the block on the shaper. Notice the lug nut holding the block in the vise. The tapered part grips it tightly and allows the flat side of the block to be pushed against the solid part of the vise.

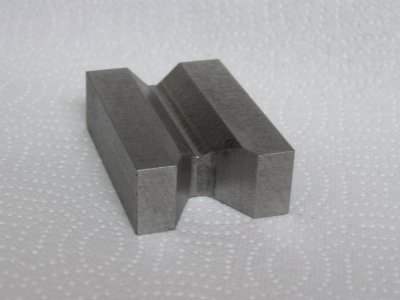

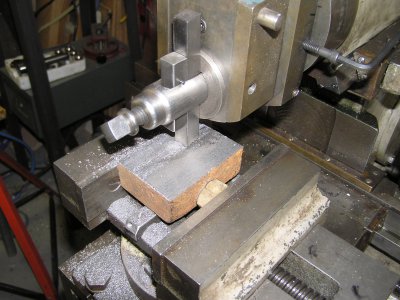

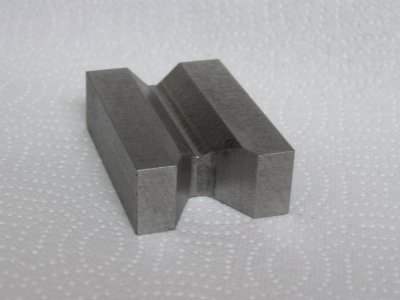

Here's the block roughed out, complete with V-grooves cut on the shaper. First time I've done angled downfeeds.

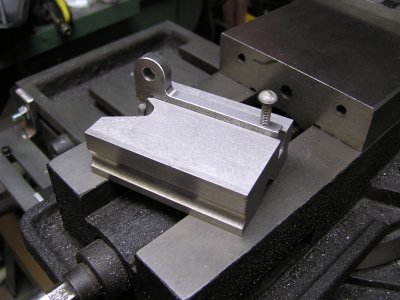

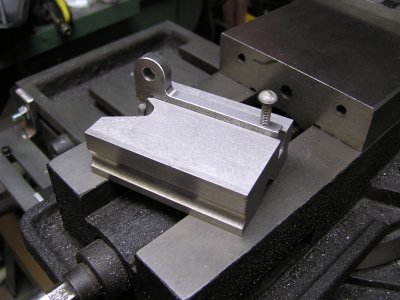

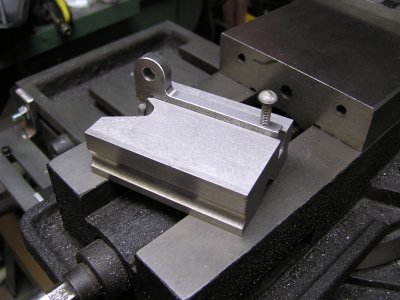

Time to cut out the fine adjuster. I really like the cheapy DROs I added to the mill. Hit "Zero", crank in the required dimension, mill it and move on. The speed control available with the VFD is pretty sweet, too.

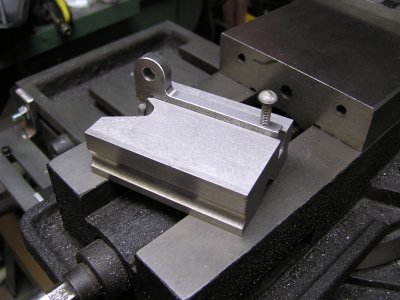

The finished base, side grooves and all, with the adjuster in place.

I got carried away with the construction and kinda forgot I had a camera, so you can fill in some of the steps. A little turning, knurling, drilling, threading, etc. and you get a pile of parts. The scriber is a piece of 5/32" music wire, tapered on a belt sander, curved at one end and hardened at the tips with an oil quench.

The assembled surface gauge. The scriber clamp with also take the small holder that came with my test indicator.

Cleaning up the block on the shaper. Notice the lug nut holding the block in the vise. The tapered part grips it tightly and allows the flat side of the block to be pushed against the solid part of the vise.

Here's the block roughed out, complete with V-grooves cut on the shaper. First time I've done angled downfeeds.

Time to cut out the fine adjuster. I really like the cheapy DROs I added to the mill. Hit "Zero", crank in the required dimension, mill it and move on. The speed control available with the VFD is pretty sweet, too.

The finished base, side grooves and all, with the adjuster in place.

I got carried away with the construction and kinda forgot I had a camera, so you can fill in some of the steps. A little turning, knurling, drilling, threading, etc. and you get a pile of parts. The scriber is a piece of 5/32" music wire, tapered on a belt sander, curved at one end and hardened at the tips with an oil quench.

The assembled surface gauge. The scriber clamp with also take the small holder that came with my test indicator.