I received the 1/2" mt2 endmill holder. I cut down a grade 8 screw to make a button to eject the taper just like the tang usually does. My spring loaded tap guide will live in it. I'll have to wait until next week to get the rest of them.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stupid simple project taught me a lot

- Thread starter Batmanacw

- Start date

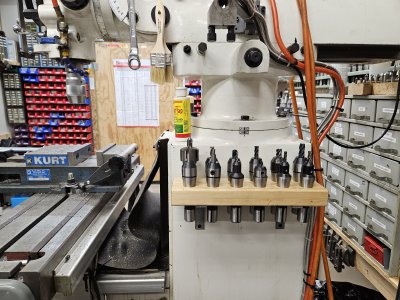

Received my mt2 rack and the mt2 to 3/8-24 chuck adapter. Now I have a 3/8" and two 1/2" chucks on their own tapers.

I have a #4 center drill and will have a #3 center drill, both in there own tapers.

I will have two sizes of 90⁰ chamfer cutters in their own tapers once the mt2 endmill holders arrive.

The spring tap guide is in its 1/2" endmill holder.

The position is near perfect. Grab a tool and drop it back into its home when done. I'm extremely pleased.

I have a #4 center drill and will have a #3 center drill, both in there own tapers.

I will have two sizes of 90⁰ chamfer cutters in their own tapers once the mt2 endmill holders arrive.

The spring tap guide is in its 1/2" endmill holder.

The position is near perfect. Grab a tool and drop it back into its home when done. I'm extremely pleased.

- Joined

- Dec 18, 2022

- Messages

- 1,729

I broke down and bought a set of Accusize R8 collets, it was a good buy. The only time I use a chuck is for odd ball stuff and odd sized drill bits.I have a drill chuck on an R8 and two on straight shanks. I also have an R8 to mt2 adapter. Now I'll have 3 on mt2.

If I was going to do a bunch of tool changes on the mill I'd use my er16 and er20 collet chucks to hold all the different tools.

Stefan Gotteswinter mounts drills in Morse taper toolpost holders instead of the tailstock for the same reason: It saves him time on tool changes. Moving the carriage back and forth is much faster than moving the tailstock back and forth. I think he still uses a chuck on it, though. (An Albrecht.)

Rick "has one of those holders but hasn't tried it out yet" Denney

Rick "has one of those holders but hasn't tried it out yet" Denney

Stefan Gotteswinter mounts drills in Morse taper toolpost holders instead of the tailstock for the same reason: It saves him time on tool changes. Moving the carriage back and forth is much faster than moving the tailstock back and forth. I think he still uses a chuck on it, though. (An Albrecht.)

Rick "has one of those holders but hasn't tried it out yet" Denney

I used a quick change tool post mt3 on my old lathe. It had the power to push a drill with power feed but I didn't want to try that on my little lathe. It might work just fine. The tool post holders are pretty expensive.

- Joined

- Dec 18, 2022

- Messages

- 1,729

I see you have spaced your DRO Scale out to get to your cross slide lock, this is something IO need to do as well. I also nee to build an extension for my tail stock quill because the DRO scale and extensions make it too short.I am extremely happy with how this came out.

View attachment 474000

View attachment 474003

I have a no 3 and no 4 center drill in their own tapers, two different sizes of chamfer tools, and 3 drill chucks. That and my spring tap guide.

Stefan Gotteswinter mounts drills in Morse taper toolpost holders instead of the tailstock for the same reason: It saves him time on tool changes. Moving the carriage back and forth is much faster than moving the tailstock back and forth. I think he still uses a chuck on it, though. (An Albrecht.)

Rick "has one of those holders but hasn't tried it out yet" Denney

I went ahead and ordered a Shars 250-105 with a mt2 for my qctp. I'm hoping I can pop the tapers out pretty easily. If I cannot I'll modify it so I can.

I may set up my absolute x zero as the center of the spindle in a repeatable way.