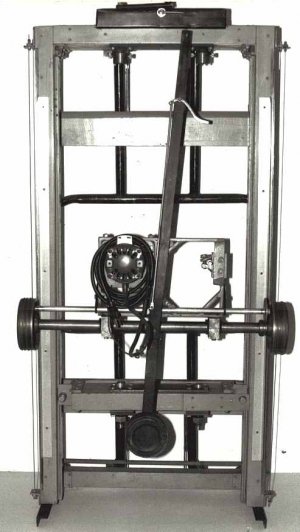

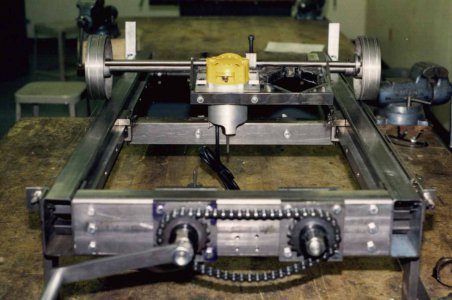

Some of may have read my article on how to make a stock by hand. I started in 1981 designing a simple stock machine which could be made by a small shop. By 1983 it was running very well after making several modifications. I wanted a machine that could be stored out of the way against a wall so it needed to fold up and stand on its end. It had to be light enough to move by one person. I picked hard maple for the frame. Old wood machines that I had seen used wood as a base so why wouldn't a duplicator work that same way. My first experience was a North Star carver which I had to assemble a new one out of the box. Later own I bought a used North Star. The area for a North Star carver is about 64 square ft of floor space all the time. My little carver will stand up in about 4 square ft of floor space and opened up will use about 35 sq, ft. Mine designed machine weights in about 135 lbs. It proved to be easy to operate and I cut over size by .025 on the outside and undersize for inletting by about the same amount. It can cut a blank into a semi inletted 95% stock in about 1:15 minutes.