- Joined

- Feb 2, 2013

- Messages

- 3,627

Hi guys,

This project is not about CNC on a machine tool, rather about a bipolar NEMA 34 stepper motor similar to what are used with CNC machine tools.

i work on industrial packaging equipment from many different manufacturers,

as you already may have known.

This time i had a scale indexer that had an aging NEMA 34 stepper motor that was not operating at acceptable speeds, the motors operating temperature was a little hot as well, but the motor did still function. troubleshooting left the motor as the fault.

upon removal, i grabbed the shaft and it didn't turn freely.

After a call to the scale indexer manufacturer for a replacement motor, i nearly fell over when they quoted a price of $600.00 for a replacement-my cost

i said absolutely no way, i'll find another one or i'll fix it.....

i chose route 2, (like just about always )

)

i started off with disassembly.

the photographic evidence:

as you can readily see, there is not much inside a stepper motor.

At the top you have the motor winding assembly.

in this motor design it is has a 4 lead winding.

the motor case is constructed from steel and the windings are copper alloy.

there was no evidence of shorted windings- i gave the windings a passing grade after thorough inspection and testing.

on the lower left, we have the drive end endcap

lower center, we have the rotor assembly

mid right we have the distal endcap

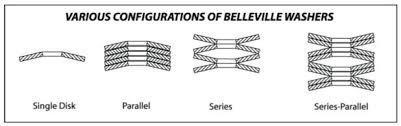

low right we have the bellville washer (edit: wave spring) that keeps the rotor's endplay to acceptable levels when assembled.

heres a close up of the rotor assembly.

it is constructed of a steel shaft with 4 segmented , permanent magnetic rings stacked up.

the bearings are common 6201ZZ C3 metric ball bearings.

the drive end of the shaft is 8mm in diameter and has a flat for mounting pulleys.

a closer look at the windings.

this is the drive end, the motor is held together by 4, 4mm x 100mm flat head machine screws. the countersunk holes are where the housing screws are utilized.

this is the inside view

the belleville washer (edit: wave spring) is inserted into the bore to control rotor endplay.

the bellville washer (edit: wave spring) puts spring tension on the rotor to keep it centered but also allow for slight torsional movement under load.

another shot of the rotor displaying the faulty bearing, a 6201ZZ.

i replaced both bearings for less than $20.

i reassembled and tested the motor. A OK

the motor is back in service for possibly another 8 years of service!

thanks for reading!

This project is not about CNC on a machine tool, rather about a bipolar NEMA 34 stepper motor similar to what are used with CNC machine tools.

i work on industrial packaging equipment from many different manufacturers,

as you already may have known.

This time i had a scale indexer that had an aging NEMA 34 stepper motor that was not operating at acceptable speeds, the motors operating temperature was a little hot as well, but the motor did still function. troubleshooting left the motor as the fault.

upon removal, i grabbed the shaft and it didn't turn freely.

After a call to the scale indexer manufacturer for a replacement motor, i nearly fell over when they quoted a price of $600.00 for a replacement-my cost

i said absolutely no way, i'll find another one or i'll fix it.....

i chose route 2, (like just about always

)

)i started off with disassembly.

the photographic evidence:

as you can readily see, there is not much inside a stepper motor.

At the top you have the motor winding assembly.

in this motor design it is has a 4 lead winding.

the motor case is constructed from steel and the windings are copper alloy.

there was no evidence of shorted windings- i gave the windings a passing grade after thorough inspection and testing.

on the lower left, we have the drive end endcap

lower center, we have the rotor assembly

mid right we have the distal endcap

low right we have the bellville washer (edit: wave spring) that keeps the rotor's endplay to acceptable levels when assembled.

heres a close up of the rotor assembly.

it is constructed of a steel shaft with 4 segmented , permanent magnetic rings stacked up.

the bearings are common 6201ZZ C3 metric ball bearings.

the drive end of the shaft is 8mm in diameter and has a flat for mounting pulleys.

a closer look at the windings.

this is the drive end, the motor is held together by 4, 4mm x 100mm flat head machine screws. the countersunk holes are where the housing screws are utilized.

this is the inside view

the belleville washer (edit: wave spring) is inserted into the bore to control rotor endplay.

the bellville washer (edit: wave spring) puts spring tension on the rotor to keep it centered but also allow for slight torsional movement under load.

another shot of the rotor displaying the faulty bearing, a 6201ZZ.

i replaced both bearings for less than $20.

i reassembled and tested the motor. A OK

the motor is back in service for possibly another 8 years of service!

thanks for reading!

Last edited: