- Joined

- Dec 26, 2016

- Messages

- 2,015

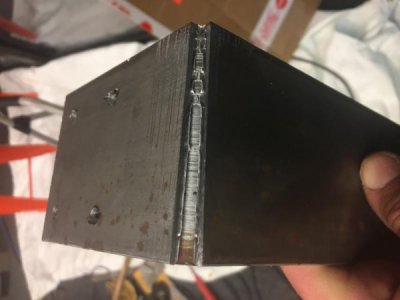

I found this topic on a welding forum and although I had heard of it but never seen it until today:

They are supposedly called" lamellar tear" googled it and found this:

Lamellar tearing is a material deficiency that can lead to brittle fracture in particular types of structural steel element assemblies.

Some of you might know exactly what it is but as I mentioned I had only heard it could happen if different alloy are used in combination of wrong heat treatment during its formation.

Just thought you might find it interesting.

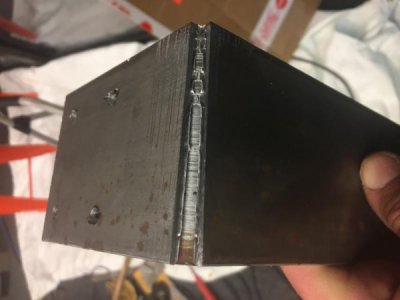

They are supposedly called" lamellar tear" googled it and found this:

Lamellar tearing is a material deficiency that can lead to brittle fracture in particular types of structural steel element assemblies.

Some of you might know exactly what it is but as I mentioned I had only heard it could happen if different alloy are used in combination of wrong heat treatment during its formation.

Just thought you might find it interesting.