& have some questions. 1st, this will be a slow build, as I'll be out of state and out of country several times and don't get as much time as some of you retired folk

so I used the Marquette stick welder to attach square tube for the vertical and horizontal aspects of the frame. I could have gone with just single tube but I'd rather overbuild it rather than wonder

the tubes were from some type of Weider sports equipment someone threw away & I rescued. I used a bedframe for a small section to fill in that missing chunk you see on the weld table

I decided to bolt the horizontal/vertical frame together (not yet done) rather than weld it together. This will allow for moving it should the need occur and it will be less rigid, should I be off the mark some

I'm numbering my questions for easier reference...

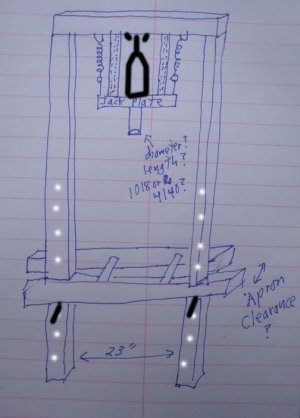

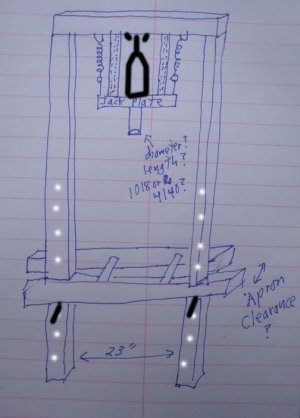

1. regarding the press bar in the sketch, I didn't know what diameter, length or type steel to make it from so that is yet to be decided

2. I think for the jack plate or stand, it will move up and down via pipe inside pipe method that I've seen a small minority of press builders do. The problem for this new welder (me) is how to secure the pipes so they don't move on me and stay perpendicular all around. Guess I'll tack weld one side then the other. That's my only concern there

3. As for the opening in the apron, there's about 5 or 6 inches of space. Not sure what the pros and cons are of the opening clearance

4. I've got a 6-ton A frame from HF that has a stability plate in it. In most press builds I've seen that is absent. It seems it is there to guide the press bar down and keep it in line. However, it sure takes up a lot of space that could better be served with more press clearance. Anyone know why they designed it that way?

I'm going to make my die from 2 railway tie plates welded together so the top and bottom of the die are the flat sides of the tie plate. Then I'm going to oxy-acy cut the various shapes I need

Since this is a slow build, this post may get buried for a few week or longer & I'll resurect it as I continue; hope that is OK with moderators

so I used the Marquette stick welder to attach square tube for the vertical and horizontal aspects of the frame. I could have gone with just single tube but I'd rather overbuild it rather than wonder

the tubes were from some type of Weider sports equipment someone threw away & I rescued. I used a bedframe for a small section to fill in that missing chunk you see on the weld table

I decided to bolt the horizontal/vertical frame together (not yet done) rather than weld it together. This will allow for moving it should the need occur and it will be less rigid, should I be off the mark some

I'm numbering my questions for easier reference...

1. regarding the press bar in the sketch, I didn't know what diameter, length or type steel to make it from so that is yet to be decided

2. I think for the jack plate or stand, it will move up and down via pipe inside pipe method that I've seen a small minority of press builders do. The problem for this new welder (me) is how to secure the pipes so they don't move on me and stay perpendicular all around. Guess I'll tack weld one side then the other. That's my only concern there

3. As for the opening in the apron, there's about 5 or 6 inches of space. Not sure what the pros and cons are of the opening clearance

4. I've got a 6-ton A frame from HF that has a stability plate in it. In most press builds I've seen that is absent. It seems it is there to guide the press bar down and keep it in line. However, it sure takes up a lot of space that could better be served with more press clearance. Anyone know why they designed it that way?

I'm going to make my die from 2 railway tie plates welded together so the top and bottom of the die are the flat sides of the tie plate. Then I'm going to oxy-acy cut the various shapes I need

Since this is a slow build, this post may get buried for a few week or longer & I'll resurect it as I continue; hope that is OK with moderators