In my limited experience with the small mills, such as Grizzly G0704, you don't have good control of the

down feed of the quill. And no hard stop. You can't lower the head on the column very carefully

to get an accurate depth change, because of stiction in the ways. It's hard to move a cutter

down a known amount. You measure something and know you want to take off .003" more.

Now what do you do?

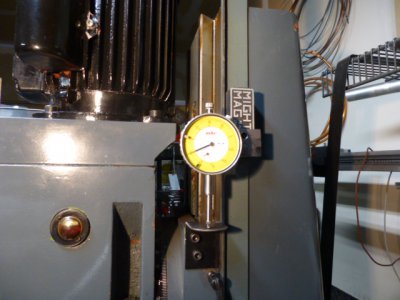

With a knee mill like the Bridgeport you can raise the knee, carefully and against gravity while

watching an indicator, to get an accurate change in cut.

And the working envelope is just so small on the smaller mills.

Bill

down feed of the quill. And no hard stop. You can't lower the head on the column very carefully

to get an accurate depth change, because of stiction in the ways. It's hard to move a cutter

down a known amount. You measure something and know you want to take off .003" more.

Now what do you do?

With a knee mill like the Bridgeport you can raise the knee, carefully and against gravity while

watching an indicator, to get an accurate change in cut.

And the working envelope is just so small on the smaller mills.

Bill