- Joined

- Sep 23, 2010

- Messages

- 280

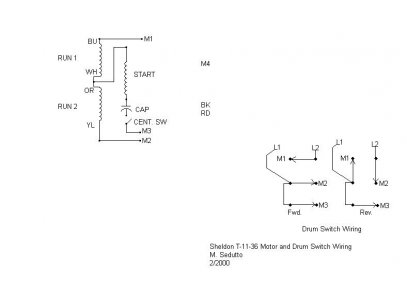

I have a South bend lathe,single phase that has no drum switch. It was set up 220 single phase with a big cuttler Hammer on/off switch.The switch is actually a 3 phase switch with only 2 connections in the switch being used. That is another question as I failed to note which of the connections were used for single phase 220 (L1,L2,L3)? Another question is ,can a pushbutton switch (stop/ forward/reverse) 3 button switch be used instead of a drum switch? I'd like to be able to use reverse. This is a D1-4 spindle machine. It seems it would work as well if not better than the drum switch. I believe there are 3 seperate 2 contact switches in it. That said ,I am no motor expert. I am not sure if I will run it at 120 or 220 single phase at this point. I only have so much breaker panel room and already have 2 - 220 v single phase circuits. Motor is a 1 1/2 hp. Again,I have minimal motor expierience but I am ok working with them and electricity. Can any experts offer some guidance? Ski