- Joined

- Jan 1, 2014

- Messages

- 233

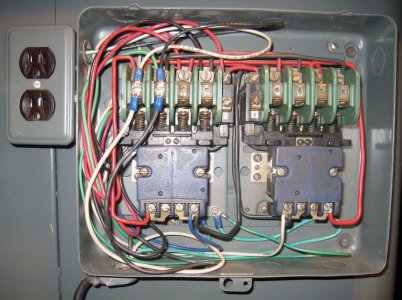

Am a novice at computers and was frustrated when trying to post my "Intro" with pictures. Maybe doing too much all at once. Anyways, here is a picture (hopefully) of my 1963 SB toolroom lathe. I bought it out of gov surplus in 1975. It had come off a navy repair ship. Missing one collet, collet nose piece, nose nut and the quick release collet lever was a bit squashed on the threaded end. 3 jaw chuck was missing the outside jaws and it did not have a 4 jaw chuck. Drive belt was cut to facilitate disassembly and moving. Of course it was painted navy grey (if it moves salute it - if it doesn't move paint it). Had heavy 3 ph 550V electrical panel on the back. All in all it was in good shape, just needed some TLC.

Sent to SB and got a parts manual and took it apart for cleanup and repaint.

Mods included gutting the electrical box(unbelievable number of wires) and using the contractor block solenoids (lucky that they operate on 115V 60hz) to control a 1 1/2hp single phase motor with the original start/stop box. Put a quick release lever on the motor belt to take the tension off the V belt when not in use, shortened the flat belt external lever shaft to put the lever closer to the cabinet and made the handle flip 90 degrees on a spring loaded ball. Now nothing is in the way of my knee when using the lathe.

Hope you find this interesting.

Sent to SB and got a parts manual and took it apart for cleanup and repaint.

Mods included gutting the electrical box(unbelievable number of wires) and using the contractor block solenoids (lucky that they operate on 115V 60hz) to control a 1 1/2hp single phase motor with the original start/stop box. Put a quick release lever on the motor belt to take the tension off the V belt when not in use, shortened the flat belt external lever shaft to put the lever closer to the cabinet and made the handle flip 90 degrees on a spring loaded ball. Now nothing is in the way of my knee when using the lathe.

Hope you find this interesting.