Like many here, I took possession of a PM-932 a few weeks ago. This is my first real piece of machinery (not counting the tiny 7x10 Hazard Fraught lathe I bought on a whim, which sits mostly unused until I can convince myself to put the purchase price's worth of mods in it, just to make it a usable machine... but I digress), and marks my first serious intent to venture into the world of metalworking. I normally hate to admit stupidity, but I'm an electrical guy by trade and I'm a bit lost with some of this stuff, so I guess I'll swallow my pride and commence the questions

First off... The machine comes with a box of goodies. In the box is the drill chuck and arbor, and a second arbor with a thread in the business end and some steel blocks with socket head screws counterbored into them on the sides. For the life of me I cannot figure out the function of this arbor! Someone care to enlighten me?

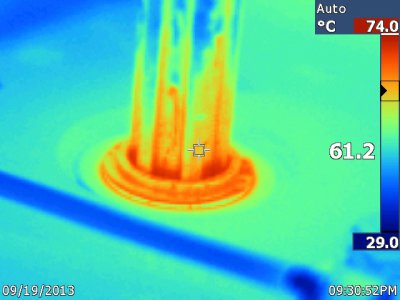

Next. How much oil should be in the gear head? I think the manual says halfway up the sight glass. Mine is closer to a quarter or third up the sight glass, is that OK or am I inadvertently starving the top of the gearset of lubricant?

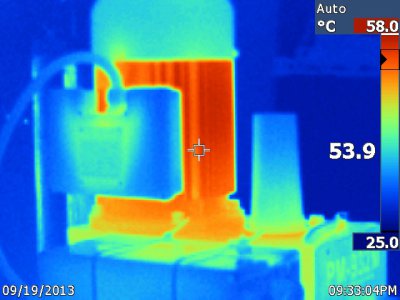

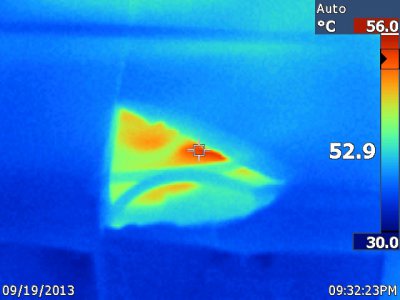

I ask the former question as a precursor to this one. During prolonged usage, the head gets quite warm, warmer than I would expect for something which does not contain an electrical load. Granted, the motor fan does blow down onto the top of the head, so is this the source of the heat, or does the gearbox in fact get quite warm of its own accord, or maybe does something have more friction than it should? The head is not what I would call "quiet" in operation, although I don't have any baseline for how it "should" sound. It's certainly much louder than a drill press.

Has anyone built a coolant system for this unit, since it is not included? Is there a standard reference design lurking around here somewhere?

Early next year will see the addition of a DRO. Is there any particular advantage to the Easson ES-12 type that makes it worth two or three hundred dollars more than a traditional segment-type display?

There's a couple of other things on my mind, but I think I'll read over the Grizzly manual a couple of times to avoid asking too many questions that can be easily found. Thanks in advance!

First off... The machine comes with a box of goodies. In the box is the drill chuck and arbor, and a second arbor with a thread in the business end and some steel blocks with socket head screws counterbored into them on the sides. For the life of me I cannot figure out the function of this arbor! Someone care to enlighten me?

Next. How much oil should be in the gear head? I think the manual says halfway up the sight glass. Mine is closer to a quarter or third up the sight glass, is that OK or am I inadvertently starving the top of the gearset of lubricant?

I ask the former question as a precursor to this one. During prolonged usage, the head gets quite warm, warmer than I would expect for something which does not contain an electrical load. Granted, the motor fan does blow down onto the top of the head, so is this the source of the heat, or does the gearbox in fact get quite warm of its own accord, or maybe does something have more friction than it should? The head is not what I would call "quiet" in operation, although I don't have any baseline for how it "should" sound. It's certainly much louder than a drill press.

Has anyone built a coolant system for this unit, since it is not included? Is there a standard reference design lurking around here somewhere?

Early next year will see the addition of a DRO. Is there any particular advantage to the Easson ES-12 type that makes it worth two or three hundred dollars more than a traditional segment-type display?

There's a couple of other things on my mind, but I think I'll read over the Grizzly manual a couple of times to avoid asking too many questions that can be easily found. Thanks in advance!