- Joined

- May 29, 2014

- Messages

- 188

Hello group.

About a week ago I posted a thread called "Shop Projects". In it, I showed a few of the things I have created, and near the end, I asked for assistance with wiring the OEM motor from my PM 1236 for use on a home-grown belt grinder. A couple of responses came; but, I do not know enough about electricity to continue until I get some (exact) directions.

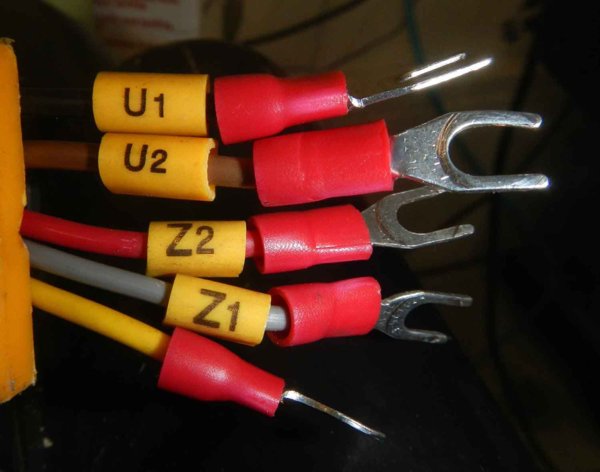

Being a bit frustrated, I attempted to connect the motor to the power last evening. There are 4 wires plus ground coming out of the motor. (NOTHING HAS CHANGED WITH ANY OF THE WIRING FROM THE FACTORY, AND THE MOTOR RAN WHEN I REMOVED IT IN THE SPRING.) Here is a pic of those 5 wires.

I am not hung up on using the wiring that is currently attached to the motor; however, since it was there, I figured it would simply be a matter of connecting them to the power source. I tried every possible combination of two wires with nothing occurring most of the time. Two times, the motor buzzed, but did not rotate. (I only allowed the buzzing to continue for about 1 second.) (NO SMOKE!!)

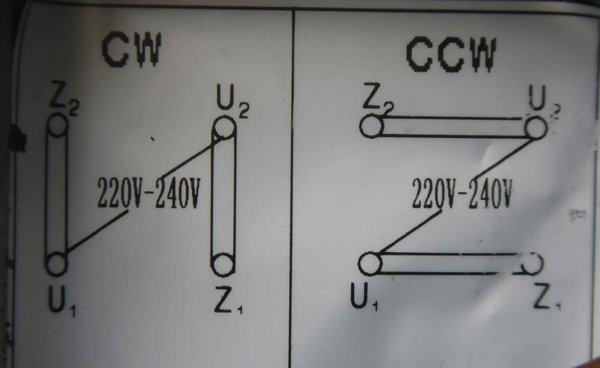

This evening, I went out to the shop & removed the cover from the wiring on the motor. There is a wiring diagram inside it. Below is a picture of the diagram.

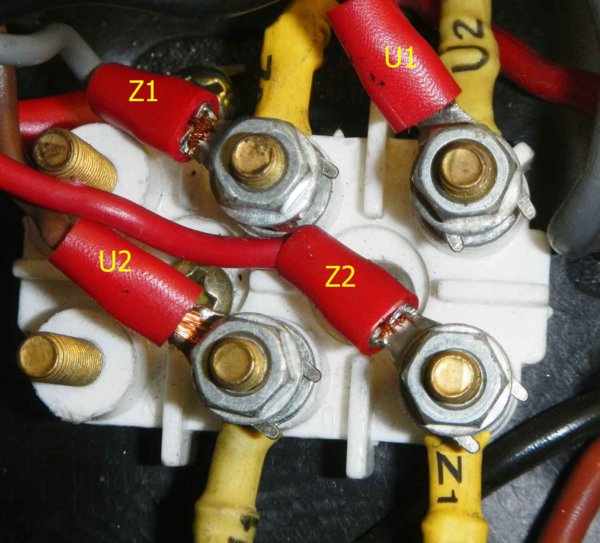

Next, is a picture of the actual wiring of the motor, including those that originally ran to the switch on the lathe. I labeled the wires with the correct designation from the other end (Top Pic).

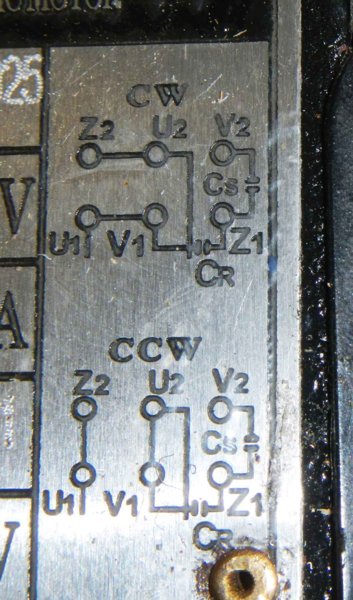

And last, a pic of the placard on the motor case.

So, I ask again, for help in making the motor run (CCW Only) and not letting any magic blue smoke out.

Since I freely admit to being "dumb as a box of rocks" with electricity, PLEASE be very specific with any instructions--IN OTHER WORDS--Treat me like an idiot.

Thanks,

Jerry in Delaware

About a week ago I posted a thread called "Shop Projects". In it, I showed a few of the things I have created, and near the end, I asked for assistance with wiring the OEM motor from my PM 1236 for use on a home-grown belt grinder. A couple of responses came; but, I do not know enough about electricity to continue until I get some (exact) directions.

Being a bit frustrated, I attempted to connect the motor to the power last evening. There are 4 wires plus ground coming out of the motor. (NOTHING HAS CHANGED WITH ANY OF THE WIRING FROM THE FACTORY, AND THE MOTOR RAN WHEN I REMOVED IT IN THE SPRING.) Here is a pic of those 5 wires.

I am not hung up on using the wiring that is currently attached to the motor; however, since it was there, I figured it would simply be a matter of connecting them to the power source. I tried every possible combination of two wires with nothing occurring most of the time. Two times, the motor buzzed, but did not rotate. (I only allowed the buzzing to continue for about 1 second.) (NO SMOKE!!)

This evening, I went out to the shop & removed the cover from the wiring on the motor. There is a wiring diagram inside it. Below is a picture of the diagram.

Next, is a picture of the actual wiring of the motor, including those that originally ran to the switch on the lathe. I labeled the wires with the correct designation from the other end (Top Pic).

And last, a pic of the placard on the motor case.

So, I ask again, for help in making the motor run (CCW Only) and not letting any magic blue smoke out.

Since I freely admit to being "dumb as a box of rocks" with electricity, PLEASE be very specific with any instructions--IN OTHER WORDS--Treat me like an idiot.

Thanks,

Jerry in Delaware