- Joined

- May 7, 2014

- Messages

- 776

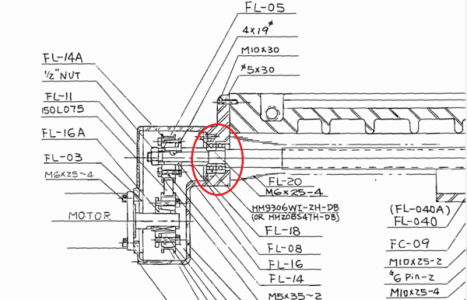

On the thread 1 or 2 below I cover taking the Table off the Supermax YMC-30 Checking and repairing a few minor things. The table had developed .005 in X backlash over about a years time.

After putting the table back on, I seem to have this horrible 3/4 turn before the table moves. Everything went back on the same way. I'm sure it's something simple, but I have done a disassy/Reassy 2x now, and I am stumped.

I've loosened the gibs way up.. moved the table around... I just cannot seem to figure out where the sudden slop came from.

On the far end, (non-motor) side of X, if you spin the knob CCW, I notice the wheel knob actually spins out 1/16th or so.(gap).then the table moves right Then you turn the knob back in till it stops and then the table moves. Maybe I need to pull that side apart as well?

Thanks for any tips. Will get a video up if I run out of thoughts, ideas, etc.

After putting the table back on, I seem to have this horrible 3/4 turn before the table moves. Everything went back on the same way. I'm sure it's something simple, but I have done a disassy/Reassy 2x now, and I am stumped.

I've loosened the gibs way up.. moved the table around... I just cannot seem to figure out where the sudden slop came from.

On the far end, (non-motor) side of X, if you spin the knob CCW, I notice the wheel knob actually spins out 1/16th or so.(gap).then the table moves right Then you turn the knob back in till it stops and then the table moves. Maybe I need to pull that side apart as well?

Thanks for any tips. Will get a video up if I run out of thoughts, ideas, etc.

Where the Dancing Bananna!!!! Dang, Love that guy. SUCCESS. Turns like a dream! Cannot feel any lash any longer...

Where the Dancing Bananna!!!! Dang, Love that guy. SUCCESS. Turns like a dream! Cannot feel any lash any longer...