- Joined

- Jun 23, 2011

- Messages

- 786

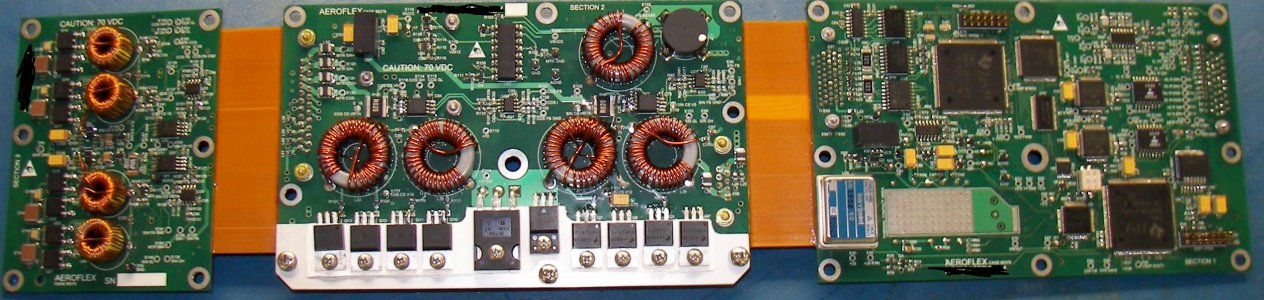

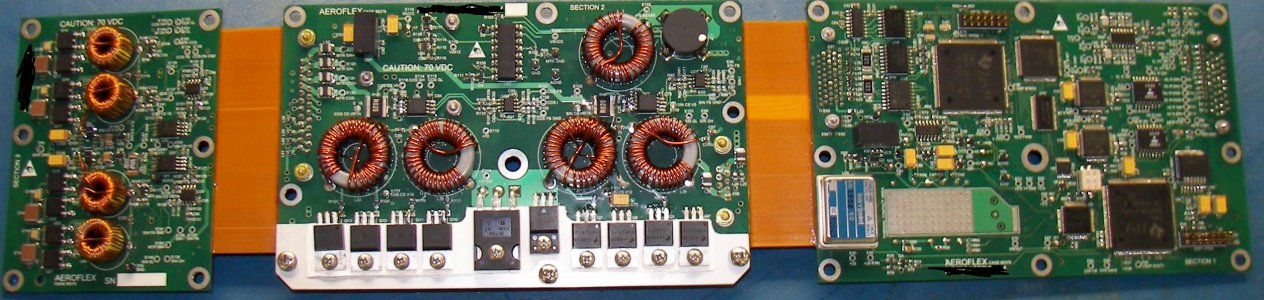

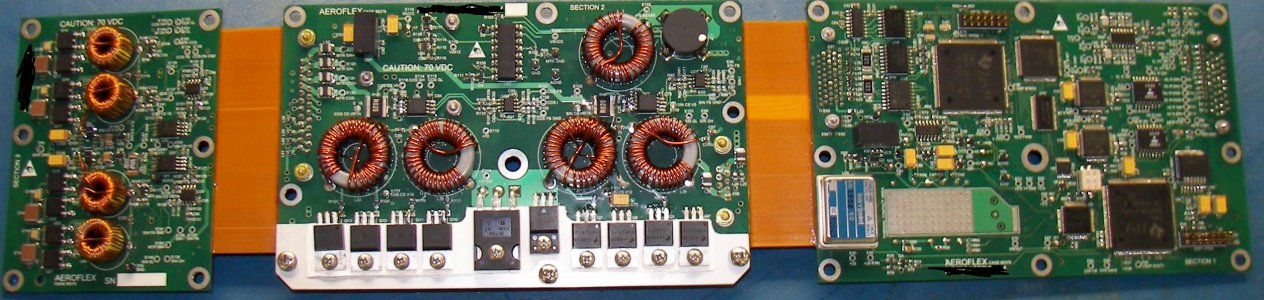

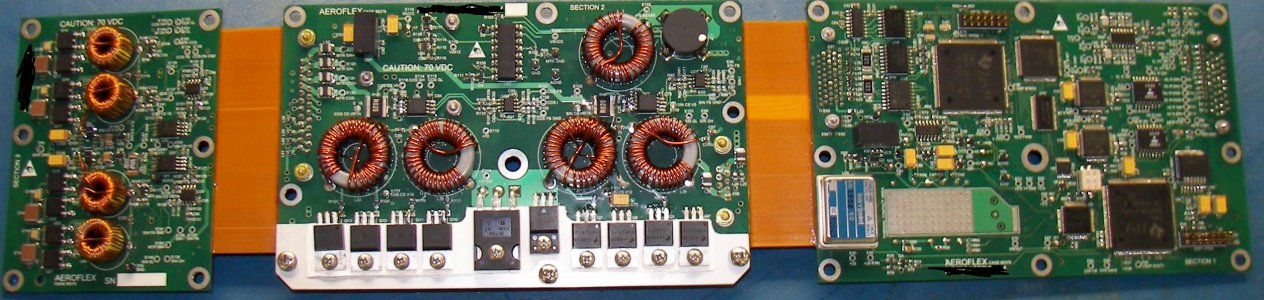

Here's a board I designed and laid out a year or two ago. It's a two axis brushless servo motor controller used for a missile countermeasure system. It employs rigid-flex technology and PWM based motor drive. The boards wrap around the countermeasure head. The two quad flatpack IC's on the right side are TI DSP ICs. The aluminum bracket is a thermal path to the chassis and the perforated area on the right segment is a thermal via array to conduct heat away from a DC/DC converter located on the back side to a sil pad boss on the outer chassis. Resolvers are used for position feedback. It is able to slew a 9 lb inertia 180 degrees in 150 milliseconds with no overshoot. It can deliver up to 1.2 kW operating on 28 VDC/70 VDC supplies. Most discrete SMT components are 0603. The big toriods are part of the output EMI filter. Two of four on each axis have a small secondary winding used to generate a floating MOSFET gate supply for the high side MOSFETs.

I always like to assemble the first circuit card of a new design since I can test it in stages, and also learn where there are potential assembly issues.

The point? This one was hand soldered (no paste) using 0.016 and 0.032 dia 63/37 solder, liquid rosin flux, and a Hakko FX-951.

John

I always like to assemble the first circuit card of a new design since I can test it in stages, and also learn where there are potential assembly issues.

The point? This one was hand soldered (no paste) using 0.016 and 0.032 dia 63/37 solder, liquid rosin flux, and a Hakko FX-951.

John