I have been considering the g4003g for several years. Not to get into politics, but I do have concerns about potential impacts to imported goods and so forth, and Grizzly does give veteran discounts on veteran's day, so here we are.

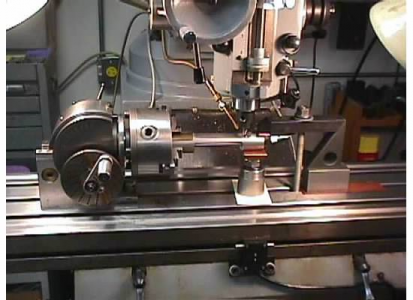

I have been considering the g4003g for several years. Not to get into politics, but I do have concerns about potential impacts to imported goods and so forth, and Grizzly does give veteran discounts on veteran's day, so here we are.I spent some time setting it up, but not enough reading on various options with the bases and leveling. It is anchored to the floor and shimmed such that the bed is within about a division or 2 on machinist level. That'll do for now, but I plan to take it down and make a adjustable foot system such as I have seen in a number of posts.

Having had the mill for about 12 years, I have a lot of various accessories, indicators, chucks, etc. I had accumulated a few dozen carbide and HSS cutters over the years for potential lathe purchase someday, so cool.

I guess next is to make test bar and see what added shimming tweaks to do now that the level is at a reasonable starting point.

I was also pondering the issue that I have 2 variables - the lathe bed twist, and whether or not the tailstock is lined up perfectly since a bar between centers won't be good if the TS is off.

Maybe I put a MT arbor in the headstock, turn what would have been the JT taper for a drill chuck to straight, indicate off the toolpost in some fashion, then put the MT item in the TS and if it's lines up with HS it should so indicate, right? That takes out any error of the chuck or its mounting?

Am I correct in thinking the MT in the HS and TS are the key indicators of alignment given chucks mount and dismount, maybe came from the discount shelf, etc?

It is interesting that after years with a mill where I select speeds and feeds based on material and goals, with the lathe I am a babe again, looking at charts and pondering the variety of variables.

Last edited: