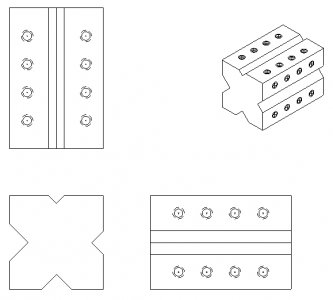

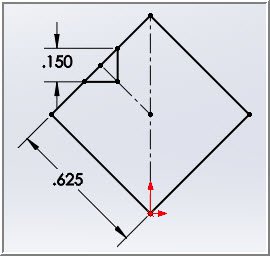

Often I find myself wanting a smaller version of the typical V block for some smallish, finicky work. The typical catalog blocks start at ~ 1.x - 1.5" in section, intending to hold say .4 - 1" round stock. Ideally I'd like something about 1/2 that scale. I have a shallow V groove ground in one of my little toolmaker vises, but its not quite the same for certain setups. I'm about to make one if I cant find anything, but thought I'd check if anyone has seen these anywhere?

ps, I've seen this system & also those round jeweler 'bench blocks, '... still not really what I'm after

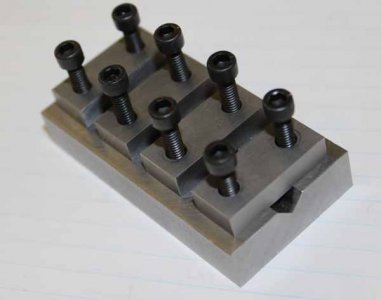

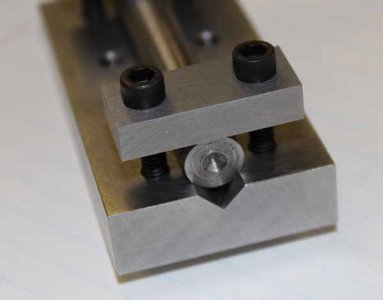

http://littlemachineshop.com/products/product_view.php?ProductID=3718&category=

ps, I've seen this system & also those round jeweler 'bench blocks, '... still not really what I'm after

http://littlemachineshop.com/products/product_view.php?ProductID=3718&category=

Steve Shannon

Steve Shannon