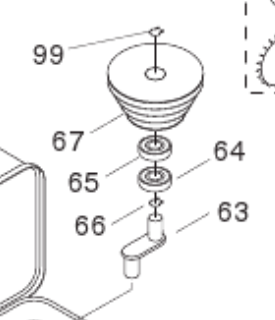

I bought the center pulley "Hi-Lo speed attachment for my 1963 Craftsman drill press when I bought it new. It just has a round piece of cast iron that goes down into the top of the column about 2". The pulley has a ball bearing in it's center. The pulley's axle is held off center in the cast iron plug,so the pulley can be rotated to tighten the front belt. The rear belt is tightened by the swinging motor mount(not the most powerful arrangement,but the motor is only 1/2 H.P..)You will probably have to make these parts,but they are do able. There is a set screw on the plug that can be tightened to jam it inside the column,but I never use it. My drill press can go from crawling speed to 10,000 RPM with the center pulley. You need VERY low speeds for drilling larger holes in steel. I think mine does about 170 RPM. But,in reality,the motor is not powerful enough to drill holes much larger than 1/2". For that,I also have an old 20" Walker Turner drill press with a VFD on it.

Most modern larger drill presses will only go down to 300 RPM,which is way too fast for drilling larger holes in steel. So,their rating of drilling ,say,1 1/4" holes is a joke. If they have powerful motors,and are 3 phase,a VFD can effectively slow them down.

Most modern larger lathes go too fast too. I did have a 19" swing lathe at work that would go 11 RPM,which was VERY useful,especially for large diameter cast iron work. Cast iron easily blunts tools if turned too fast,most especially HSS. Carbide is needed,but so is SLOW SPEED. My 16" lathe at home does 60 RPM,way too fast. It swings 24" in the gap. I made a special pulley to slow it to 1/2 speed,but even that is not slow enough. Fortunately,most of my work is not large. I am at least able to face off my large cast iron face plate(they always need a bit of truing up when new). My lathe is single phase,so I can't put a VFD on it. When I bought it,they were not yet common.