- Joined

- Dec 30, 2014

- Messages

- 259

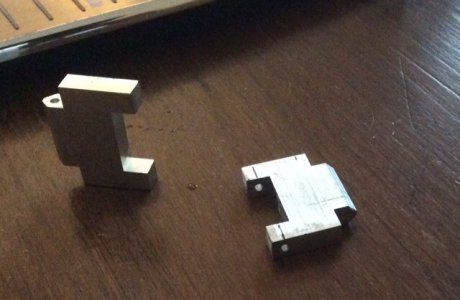

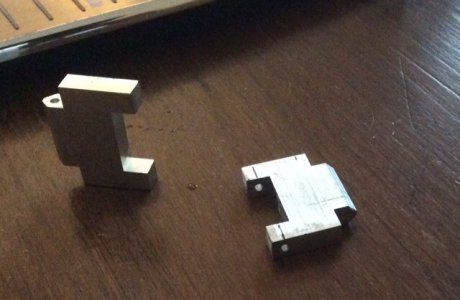

I am working on track pads for a model dragline crawler undercarriage. I cut the wide slot in one pass using a 3/4" end mill. This is 6061 and the depth is 1/4". It made me question wether there is any difference in the direction of the cut like there would be if I were side milling? What if this were a pocket? I did just barely snug up the gib lock to make sure it was steady. Also tried to reduce the size of the photo to improve loading speed. Hope it isn't too grainy.

Jim

Jim