- Joined

- May 14, 2015

- Messages

- 179

I have no idea if this is the right place for the build thread, but my home is above my shop, and this CNC project will be in it

I'll say up front this is a big, big project. Especially for something that's only the size of an oven. This first post will be a sort of rolling summary (so long as I remain able to edit it) of milestones passed & yet to be completed. I will try to mention all the questions I've had to find answers to in order to progress, so that someone embarking on a similar adventure might take a short cut. If it looks like I'm missing anything, or especially if anything needs clarification or is outright wrong, by all means speak up! My starting point is as a total ignoramus who only has a couple years' experience with a small manual lathe, and a degree in aerospace engineering. Having seen what a *well made* machine can do --even a small one-- and the near-limitless capabilities of even simple automation compared to my own abilities, I think it's worth reaching for the stars a bit.

I will have a lot of questions I'll ask here, every step of the way to be sure . I'm not posting on CNCZone since that place is lousy with abandoned machine-build threads, and it's depressing. It seems like plenty of ambitious projects happen here, and will way less pretense. Thanks in advance for tagging along, and of course for any help or advice.

. I'm not posting on CNCZone since that place is lousy with abandoned machine-build threads, and it's depressing. It seems like plenty of ambitious projects happen here, and will way less pretense. Thanks in advance for tagging along, and of course for any help or advice.

So away we go...

Overall Concept:

-Benchtop size, trying to keep it inside a 3ft cube

-Workpiece size 2" x 7.5" (with boring capacity to that depth)

-CNC lathe profiling capability, including threading/rigid tapping

-Light milling capability with a live tool (engraving, slots, helices --real word)

-4000rpm spindle (well over 1000sfm for a 1.25" 'average size' profile)

-Capable of good results on all commonly machined metals (steels, aluminum, brasses, Delrin)

-5C Collet/Closer spindle, with D1-4 mount for chucks

-Design for future; tool changer, tailstock, flood coolant, full closed loop axes, chip auger

That last one (growth capability) is why the machine isn't about 1/3 shorter.

Design Constraints: All Good Designs Have Restrictions

-Residential 110VDC/60Hz 1-PH @ 15A, grounded GFCI outlet

-3ft cube external envelope (again)

-500lb weight limit (this is flexible within reason)

-"Easily" moved; it won't be on casters, but I plan for it to have lifting points for a hoist

-Bench top; heavy wooden workbench, but no 'proper' machine platform to stiffen it (also flexible)

Design Criteria: Brass Tacks by Category

Complete Parts List (with Purchase Price):

-Used Baldor BSM80C-375AF servo motor (135$ with extra 10:1 gearing) & pulley

-Used Baldor FMH2A09TR-EN43 (267$) & cables

-Nema 23, bipolar, 381 oz-in, 3.5A steppers (tentative) & mount @40$/ea

-Galil DMC-2813 motion controller, 8 axis, ethernet interface (350$)

--Galil SDM-20640 daughter board stepper drivers, 4 axis, 3A & 50V (300$)

-Used Cherokee International QT6A1D 24VDC @ 5A, 5VDC @ 20A Power Supply (24.99$)

-48VDC @ 8A stepper driver power supply (tentative)

-12/24VDC ducted cooling fans (tentative, for servo driver & power supplies)

-16mm OD, 4mm pitch SFU1604 ballscrew & nut, 300mm X axis (30.58$)

-16mm OD, 5mm pitch SFU1605 ballscrew & nut, 500mm Z axis (76.89$)

--BK/BF12 ballscrew bearing mounts qty(2) (0$ part of Z axis order)

--Stainless steel spring coupler 1/4"-10mm, qty(2) (0$ part of Z axis order)

-28mm steel ballnut mounts for 1604/1605 ballnuts qty(2) (20.52$)

-25mm x 400mm linear guideways qty(2) & HSR20CA carraiges qty(4) , X axis (238$)

--25mm x 600mm linear guideways qty(2) & HSR20CA carraiges qty(4) , X axis (0$ part of X axis order)

-1.5" box tubing, 1/4" and 3/16" thicknesses (tentative)

-3/8" or 1/2" steel plate (tentative)

-1" steel plate for carriage & slide table surfaces (tentative)

-1" square cold roll steel bar for spacers (tentative)

-2" square aluminum bar for stepper motor mounts (tentative)

-Spindle assembly (ball bearings, spindle shaft, spindle casing, pulley)

-45x85x19mm Barden 7209/209HCDUL paired P4/ABEC7 angular contact bearings (130$)

-45x85x19mm Fafnir 6209/MM209K P4/ABEC7 deep groove bearing (80$)

Machining Envelope:

-Intended part size is 2"OD x 7.5" stickout (min cutter travel 1")

-Spindle bore pass through 1.25" diameter

-No tail stock at this time, but room to add

-Ability to move to tool changer docking position along X-axis; total travel must be 6"

-Boring depth capacity of 7.5", means Z-travel of carriage must be 15" total

Machining Capability (Forces/Power):

-Capable of machining steels, aluminums, plastics, brasses, and irons

-Carbide cutter speeds (>1000sfm, for a ~1.25" OD part is 3000rpm, so spindle = 4000rpm)

-Shallower/faster cuts acceptable so long as surface finish is not compromised (if possible)

Optimizing Rigidity:

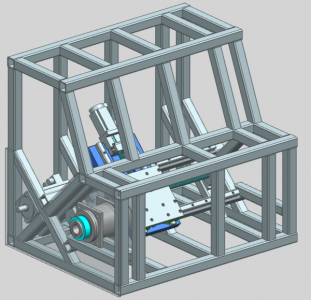

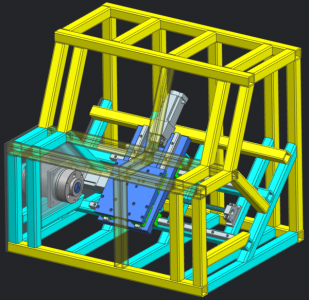

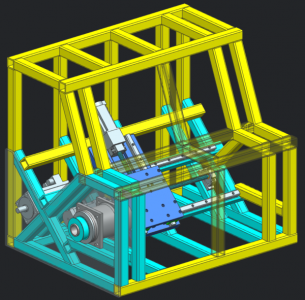

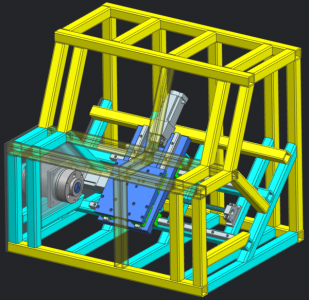

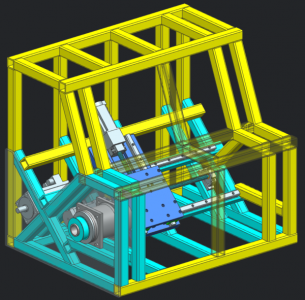

-Beefy, welded truss frame, with several hundred pounds minimum weight

-Optional attachment of mass/dampening material later (iron plate or epoxy granite)

-Heavy gauge plate steel motor & spindle mounting plates at headstock

-Thinner gauge sheet closeout bolted to exterior

-Direct-driven stepper motors

-25mm timing belt drives spindle

-16mm ballscrews, 25mm linear guideways both have far higher load capacity than needed

Optimizing Accuracy:

-Use of linear guideways to constrain axis motion with very little off-axis backlash

-Use of ballscrew drive for axes to reduce backlash (also friction)

-Use of servo motor on spindle to precisely track its position & speed for threading & milling

--May ultimately add a secondary encoder to the spindle to even more precisely monitor position

-May eventually add a second ball nut to either/both axis if the lost cut envelope is acceptable

-Addition of friction brake to spindle to hold it steady during stopped moves (slotting/side drilling)

Minimizing Size:

-Work envelope and machine travel kept to minimum practical size

-Simple single-belt spindle drivetrain

-Z-axis carriage and X-axis cross slide made from 1" steel plate with inset mounting surfaces

-45deg bed slope is the best compromise between height & depth, and a short load path down

Electrical Components:

-Baldor BSM80C-375AF Servo motor is ~1kW, with max RPM of 4000rpm, 2500 pulse/rev encoder, generating 3.6N-m continuous force, and operating at rated 6.29A & 300VAC. The power figures triple at maximum, but for a lathe such violent power moves are generally unnecessary and indicate more serious problems (crash). That, and the 1kW resultant power draw make me confident this motor won't blow my breaker in operation (inrush, perhaps). The way these AC servos operate, is a fancy VFD called a servo driver feeds them a continuous current across the whole speed range, but increases voltage to drive it harder, while increasing frequency to keep time with its spinning (greatly simplified). This constant torque quality manifests as a nearly flat torque curve across the operating range of speeds. While the motor is not hugely different from any other induction unit apart from its low inertia, the real magic of servos stems from their precise control; an encoder tracks the exact angular position & feeds that data to the servo driver in real time, where high performance control systems adjust power delivery to quickly react to applied loads on the motor or commands from the controller.

-Servo driver is a 9A unit set up for analog command signals, but digital on the inside so it is also capable of accepting step/direction inputs just like a stepper motor (which are then parsed by a computer & sent to the motor, then adjusted as the encoder reports the response). The driver actually replicates & outputs the encoder signal, so it can be sent back to the motion controller itself for a complete closed-loop of feedback for all components. The controlling input pulse is a low level signal, and the computer must be isolated from the enormous & variable motor current, so a separate 24VDC supply is necessary

Component Block Diagram:

http://hobby-machinist.com/attachments/block-diagram-png.239021/

Controls Block Diagram:

-Laptop running Mach3 CAM software -> ethernet -> motion controller

-Motion controller -> servo & stepper drivers -> servo & steppers

-24VDC power supply->motion controller, servo drive

-48VDC power supply->stepper drive

Power Consumption:

-15A 120VAC available, 16A total peak demand (dang, no tunes!)

-9A continuous draw by servo motor drive (at max power)

-2A/120VAC continuous draw by 5A-24VDC/10A-5VDC power supply

--motion controller requires 1A 5VDC

--stepper driver fans require .5A 5VDC

--servo driver requires 1A 24VDC

--servo controller cooling fan requires .25A 24VDC

-5A/120VAC max draw, I think, from 8A 48VDC power supply

--3.5A steppers (3.5*2*.67) comes to 4.7A 48VDC

Mechanical Components:

-25mm linear rails; these carriages are large enough to have zerk lube fittings, and also have external flanges that broaden their mounting footprint. They also seem to be made to a slightly higher standard than budget smaller rail sizes.

-16mm ballscrew; the 5mm pitch is plenty for my needs and the screw itself is far, far, far, far stronger than any load I'll be applying to it via the stepper motors or cutter. I wanted more control & resolution in the radial/X direction so I found a rolled 4mm screw. The balls are smaller so the load capacity is lower, but the greater number of points of contact is ultimately more rigid.

-Ballnut mounts are an off the shelf steel variety paired with my ballnuts

-Stepper motors will be mounted directly to the ballscrews on machined standoffs, the shafts connected by helical couplers

Spindle Construction:

-The spindle assy is a 'cartridge' type that is mounted into the frame in alignment with the axis rails

-The casing will be a simple hollow cylinder bored for the bearing races, with a large square mounting flange welded at each end that will bolt to the frame for mounting

-The spindle will be a 5C collet bore with space for a tubular closer, and D1-4 faceplate for chucks

-Two opposed & preloaded roller or angular contact bearings support the business end, one set of deep groove bearings support the side load of the pulley on the tail end. All are P4/ABEC7 super precision grade, and 45IDx85ODx19mmW

-All bearings will be labyrinth sealed against debris and will have lube points nearby in the casing

Tooling:

-At least initially, there will be an AXA quick change post mounted on the slide that holds the cutters

-I plan to add a quick-change capability to the surface of the slide itself, of a wedge type similar to the Aloris system, that will be operate as part of the automatic tool change system

Frame Construction:

Maintaining Alignment:

Mechanical Assembly:

Electrical Assembly:

Function Testing & Adjustment:

I'll say up front this is a big, big project. Especially for something that's only the size of an oven. This first post will be a sort of rolling summary (so long as I remain able to edit it) of milestones passed & yet to be completed. I will try to mention all the questions I've had to find answers to in order to progress, so that someone embarking on a similar adventure might take a short cut. If it looks like I'm missing anything, or especially if anything needs clarification or is outright wrong, by all means speak up! My starting point is as a total ignoramus who only has a couple years' experience with a small manual lathe, and a degree in aerospace engineering. Having seen what a *well made* machine can do --even a small one-- and the near-limitless capabilities of even simple automation compared to my own abilities, I think it's worth reaching for the stars a bit.

I will have a lot of questions I'll ask here, every step of the way to be sure

So away we go...

Overall Concept:

-Benchtop size, trying to keep it inside a 3ft cube

-Workpiece size 2" x 7.5" (with boring capacity to that depth)

-CNC lathe profiling capability, including threading/rigid tapping

-Light milling capability with a live tool (engraving, slots, helices --real word)

-4000rpm spindle (well over 1000sfm for a 1.25" 'average size' profile)

-Capable of good results on all commonly machined metals (steels, aluminum, brasses, Delrin)

-5C Collet/Closer spindle, with D1-4 mount for chucks

-Design for future; tool changer, tailstock, flood coolant, full closed loop axes, chip auger

That last one (growth capability) is why the machine isn't about 1/3 shorter.

Design Constraints: All Good Designs Have Restrictions

-Residential 110VDC/60Hz 1-PH @ 15A, grounded GFCI outlet

-3ft cube external envelope (again)

-500lb weight limit (this is flexible within reason)

-"Easily" moved; it won't be on casters, but I plan for it to have lifting points for a hoist

-Bench top; heavy wooden workbench, but no 'proper' machine platform to stiffen it (also flexible)

Design Criteria: Brass Tacks by Category

Complete Parts List (with Purchase Price):

-Used Baldor BSM80C-375AF servo motor (135$ with extra 10:1 gearing) & pulley

-Used Baldor FMH2A09TR-EN43 (267$) & cables

-Nema 23, bipolar, 381 oz-in, 3.5A steppers (tentative) & mount @40$/ea

-Galil DMC-2813 motion controller, 8 axis, ethernet interface (350$)

--Galil SDM-20640 daughter board stepper drivers, 4 axis, 3A & 50V (300$)

-Used Cherokee International QT6A1D 24VDC @ 5A, 5VDC @ 20A Power Supply (24.99$)

-48VDC @ 8A stepper driver power supply (tentative)

-12/24VDC ducted cooling fans (tentative, for servo driver & power supplies)

-16mm OD, 4mm pitch SFU1604 ballscrew & nut, 300mm X axis (30.58$)

-16mm OD, 5mm pitch SFU1605 ballscrew & nut, 500mm Z axis (76.89$)

--BK/BF12 ballscrew bearing mounts qty(2) (0$ part of Z axis order)

--Stainless steel spring coupler 1/4"-10mm, qty(2) (0$ part of Z axis order)

-28mm steel ballnut mounts for 1604/1605 ballnuts qty(2) (20.52$)

-25mm x 400mm linear guideways qty(2) & HSR20CA carraiges qty(4) , X axis (238$)

--25mm x 600mm linear guideways qty(2) & HSR20CA carraiges qty(4) , X axis (0$ part of X axis order)

-1.5" box tubing, 1/4" and 3/16" thicknesses (tentative)

-3/8" or 1/2" steel plate (tentative)

-1" steel plate for carriage & slide table surfaces (tentative)

-1" square cold roll steel bar for spacers (tentative)

-2" square aluminum bar for stepper motor mounts (tentative)

-Spindle assembly (ball bearings, spindle shaft, spindle casing, pulley)

-45x85x19mm Barden 7209/209HCDUL paired P4/ABEC7 angular contact bearings (130$)

-45x85x19mm Fafnir 6209/MM209K P4/ABEC7 deep groove bearing (80$)

Machining Envelope:

-Intended part size is 2"OD x 7.5" stickout (min cutter travel 1")

-Spindle bore pass through 1.25" diameter

-No tail stock at this time, but room to add

-Ability to move to tool changer docking position along X-axis; total travel must be 6"

-Boring depth capacity of 7.5", means Z-travel of carriage must be 15" total

Machining Capability (Forces/Power):

-Capable of machining steels, aluminums, plastics, brasses, and irons

-Carbide cutter speeds (>1000sfm, for a ~1.25" OD part is 3000rpm, so spindle = 4000rpm)

-Shallower/faster cuts acceptable so long as surface finish is not compromised (if possible)

Optimizing Rigidity:

-Beefy, welded truss frame, with several hundred pounds minimum weight

-Optional attachment of mass/dampening material later (iron plate or epoxy granite)

-Heavy gauge plate steel motor & spindle mounting plates at headstock

-Thinner gauge sheet closeout bolted to exterior

-Direct-driven stepper motors

-25mm timing belt drives spindle

-16mm ballscrews, 25mm linear guideways both have far higher load capacity than needed

Optimizing Accuracy:

-Use of linear guideways to constrain axis motion with very little off-axis backlash

-Use of ballscrew drive for axes to reduce backlash (also friction)

-Use of servo motor on spindle to precisely track its position & speed for threading & milling

--May ultimately add a secondary encoder to the spindle to even more precisely monitor position

-May eventually add a second ball nut to either/both axis if the lost cut envelope is acceptable

-Addition of friction brake to spindle to hold it steady during stopped moves (slotting/side drilling)

Minimizing Size:

-Work envelope and machine travel kept to minimum practical size

-Simple single-belt spindle drivetrain

-Z-axis carriage and X-axis cross slide made from 1" steel plate with inset mounting surfaces

-45deg bed slope is the best compromise between height & depth, and a short load path down

Electrical Components:

-Baldor BSM80C-375AF Servo motor is ~1kW, with max RPM of 4000rpm, 2500 pulse/rev encoder, generating 3.6N-m continuous force, and operating at rated 6.29A & 300VAC. The power figures triple at maximum, but for a lathe such violent power moves are generally unnecessary and indicate more serious problems (crash). That, and the 1kW resultant power draw make me confident this motor won't blow my breaker in operation (inrush, perhaps). The way these AC servos operate, is a fancy VFD called a servo driver feeds them a continuous current across the whole speed range, but increases voltage to drive it harder, while increasing frequency to keep time with its spinning (greatly simplified). This constant torque quality manifests as a nearly flat torque curve across the operating range of speeds. While the motor is not hugely different from any other induction unit apart from its low inertia, the real magic of servos stems from their precise control; an encoder tracks the exact angular position & feeds that data to the servo driver in real time, where high performance control systems adjust power delivery to quickly react to applied loads on the motor or commands from the controller.

-Servo driver is a 9A unit set up for analog command signals, but digital on the inside so it is also capable of accepting step/direction inputs just like a stepper motor (which are then parsed by a computer & sent to the motor, then adjusted as the encoder reports the response). The driver actually replicates & outputs the encoder signal, so it can be sent back to the motion controller itself for a complete closed-loop of feedback for all components. The controlling input pulse is a low level signal, and the computer must be isolated from the enormous & variable motor current, so a separate 24VDC supply is necessary

Component Block Diagram:

http://hobby-machinist.com/attachments/block-diagram-png.239021/

Controls Block Diagram:

-Laptop running Mach3 CAM software -> ethernet -> motion controller

-Motion controller -> servo & stepper drivers -> servo & steppers

-24VDC power supply->motion controller, servo drive

-48VDC power supply->stepper drive

Power Consumption:

-15A 120VAC available, 16A total peak demand (dang, no tunes!)

-9A continuous draw by servo motor drive (at max power)

-2A/120VAC continuous draw by 5A-24VDC/10A-5VDC power supply

--motion controller requires 1A 5VDC

--stepper driver fans require .5A 5VDC

--servo driver requires 1A 24VDC

--servo controller cooling fan requires .25A 24VDC

-5A/120VAC max draw, I think, from 8A 48VDC power supply

--3.5A steppers (3.5*2*.67) comes to 4.7A 48VDC

Mechanical Components:

-25mm linear rails; these carriages are large enough to have zerk lube fittings, and also have external flanges that broaden their mounting footprint. They also seem to be made to a slightly higher standard than budget smaller rail sizes.

-16mm ballscrew; the 5mm pitch is plenty for my needs and the screw itself is far, far, far, far stronger than any load I'll be applying to it via the stepper motors or cutter. I wanted more control & resolution in the radial/X direction so I found a rolled 4mm screw. The balls are smaller so the load capacity is lower, but the greater number of points of contact is ultimately more rigid.

-Ballnut mounts are an off the shelf steel variety paired with my ballnuts

-Stepper motors will be mounted directly to the ballscrews on machined standoffs, the shafts connected by helical couplers

Spindle Construction:

-The spindle assy is a 'cartridge' type that is mounted into the frame in alignment with the axis rails

-The casing will be a simple hollow cylinder bored for the bearing races, with a large square mounting flange welded at each end that will bolt to the frame for mounting

-The spindle will be a 5C collet bore with space for a tubular closer, and D1-4 faceplate for chucks

-Two opposed & preloaded roller or angular contact bearings support the business end, one set of deep groove bearings support the side load of the pulley on the tail end. All are P4/ABEC7 super precision grade, and 45IDx85ODx19mmW

-All bearings will be labyrinth sealed against debris and will have lube points nearby in the casing

Tooling:

-At least initially, there will be an AXA quick change post mounted on the slide that holds the cutters

-I plan to add a quick-change capability to the surface of the slide itself, of a wedge type similar to the Aloris system, that will be operate as part of the automatic tool change system

Frame Construction:

Maintaining Alignment:

Mechanical Assembly:

Electrical Assembly:

Function Testing & Adjustment:

Last edited: