- Joined

- Feb 5, 2015

- Messages

- 662

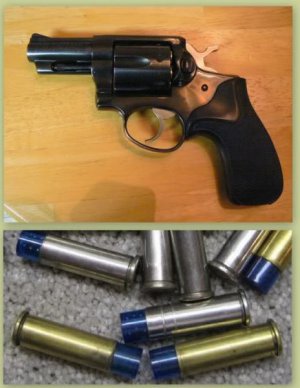

About six years ago, when my kids were back home from college, I was trying to interest my boy in some of the things that have also interested me. Although his interest in firearms has since lapsed, it was still fairly high at the time. During a casual discussion, he recalled how I used to bring a .357 Magnum revolver on our camping trips, loaded with birdshot (i.e. a "snake gun" - we never pointed it at a snake but we did kill a few tin cans, LOL). I mentioned that it was a pain to carry that heavy thing around for such a trivial purpose and he wondered why I didn't build a lighter one - a single action, single shot, hand-held shotgun.

Other than the legal issues, it seemed like a good opening for arousing an interest in both mechanical design and metalworking (at the time, he was a Freshman and hadn't declared a major yet). So I tried to use the opportunity to motivate/teach him and we sporadically worked on the project, working through the steps of how products evolve from conception through initial research and planning to design and analysis, finally to manufacturing a prototype.

The original goal was to make a simple, smoothbore .410 hand-held shotgun but that is not legal in California as we found out after some internet research. There are some limitations, among which is the requirement for a rifled barrel with a minimum length. (Oddly, we made a couple of telephone calls to local law enforcement agencies during this period and they weren't able to answer questions regarding the legal issues which leads one to wonder if anyone would ever get cited for making something that didn't meet the strict letter of the law - but that's another story, LOL.)

A much simpler project would have been a black powder smoothbore - completely legal, easy to make and easily loaded with birdshot. That wouldn't have illustrated all of the points that I hoped to make, however and - as we'll learn in a moment - maybe I made the points TOO clearly, ha-ha.

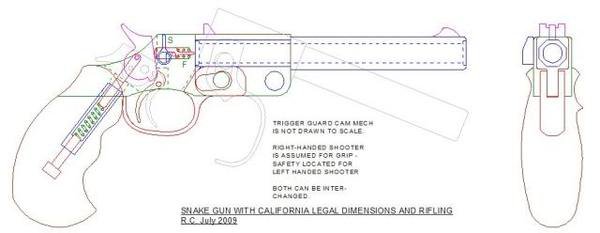

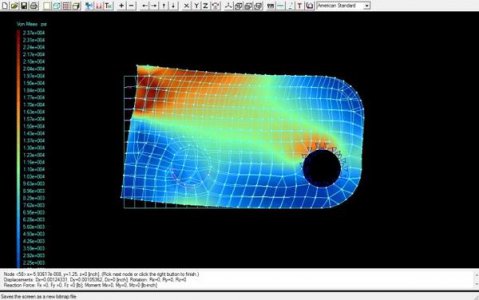

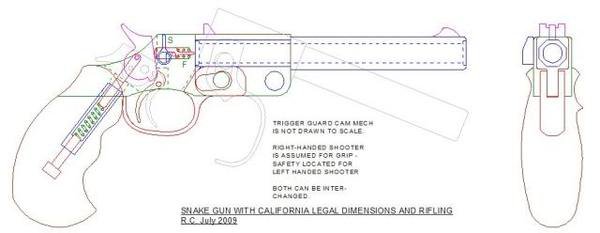

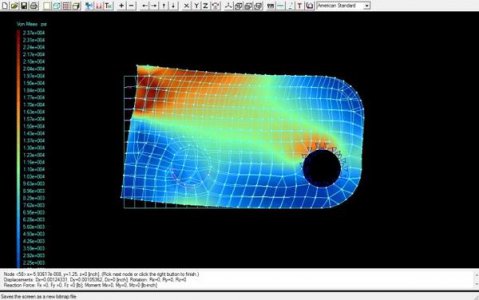

After considering how typical single-action mechanisms function, working through the selection of materials, how to represent the impulse load of the cartridge discharge and other typical problems that come up in the early stages of a design, we came up with a tentative model. The basis is a rifled barrel for a .45 Colt cartridge that can also accommodate a .410 shotshell and along the way, we developed a preliminary stress analysis using a free finite element analysis (FEA) program downloaded from the internet.

Many people regard firearms negatively and that's a matter of opinion with which I have no problem. I'm a country boy, born in New Mexico but grew up in the hills of Northeast Tennessee and had my first rifle on my eleventh birthday - about two years LATER than most of my friends.

After doing my thing in the Army (First Cavalry Division '63-'64 and Fourth Infantry Division '64-'65) I lost interest in this stuff until I discovered trap and skeet and got hooked on over/under shotguns. One thing led to another … my wife and I also started target shooting with handguns and rifles. My son shared our attitudes - he liked to punch holes in paper and break clay targets.

Another characteristic that makes firearms interesting to me and to many others is the mechanical precision and craftsmanship involved in the manufacture of fine firearms (especially side-lock shotguns - my particular fondness). Many people who are interested in firearms are attracted to developing machining skills because of their interest and the converse is equally true. OK, sorry for the diversion - other than just having fun with it, a project that could provide an incentive for my boy to make a decision about his major was useful I thought (he was wavering all over the place at this time).

Maybe this detailed exercise was too much for the boy, LOL - as it turns out, he decided on a journalism major and he's doing OK with it (had a few articles published in his college paper and in a few local newspapers). But he's no longer interested in building the "tin-can gun", as he calls it. I was cleaning out some of my drawing files on the computer tonight and came across our drawing - I thought that it might be of interest here from the aspect of a machining challenge. So here's the drawing and the preliminary stress analysis - for ENTERTAINMENT only - that we came up with:

The stress/deformation analysis was made only for the receiver. I made the assumption that it would be the weakest link in the design.

Note that the "tin-can gun" was never made; it would have been a good project to photo-document because there are a number of challenging operations involved, not only machining but hardening, grinding, stress-relieving and a LOT of hand-fitting of small parts.

Other than the legal issues, it seemed like a good opening for arousing an interest in both mechanical design and metalworking (at the time, he was a Freshman and hadn't declared a major yet). So I tried to use the opportunity to motivate/teach him and we sporadically worked on the project, working through the steps of how products evolve from conception through initial research and planning to design and analysis, finally to manufacturing a prototype.

The original goal was to make a simple, smoothbore .410 hand-held shotgun but that is not legal in California as we found out after some internet research. There are some limitations, among which is the requirement for a rifled barrel with a minimum length. (Oddly, we made a couple of telephone calls to local law enforcement agencies during this period and they weren't able to answer questions regarding the legal issues which leads one to wonder if anyone would ever get cited for making something that didn't meet the strict letter of the law - but that's another story, LOL.)

A much simpler project would have been a black powder smoothbore - completely legal, easy to make and easily loaded with birdshot. That wouldn't have illustrated all of the points that I hoped to make, however and - as we'll learn in a moment - maybe I made the points TOO clearly, ha-ha.

After considering how typical single-action mechanisms function, working through the selection of materials, how to represent the impulse load of the cartridge discharge and other typical problems that come up in the early stages of a design, we came up with a tentative model. The basis is a rifled barrel for a .45 Colt cartridge that can also accommodate a .410 shotshell and along the way, we developed a preliminary stress analysis using a free finite element analysis (FEA) program downloaded from the internet.

Many people regard firearms negatively and that's a matter of opinion with which I have no problem. I'm a country boy, born in New Mexico but grew up in the hills of Northeast Tennessee and had my first rifle on my eleventh birthday - about two years LATER than most of my friends.

After doing my thing in the Army (First Cavalry Division '63-'64 and Fourth Infantry Division '64-'65) I lost interest in this stuff until I discovered trap and skeet and got hooked on over/under shotguns. One thing led to another … my wife and I also started target shooting with handguns and rifles. My son shared our attitudes - he liked to punch holes in paper and break clay targets.

Another characteristic that makes firearms interesting to me and to many others is the mechanical precision and craftsmanship involved in the manufacture of fine firearms (especially side-lock shotguns - my particular fondness). Many people who are interested in firearms are attracted to developing machining skills because of their interest and the converse is equally true. OK, sorry for the diversion - other than just having fun with it, a project that could provide an incentive for my boy to make a decision about his major was useful I thought (he was wavering all over the place at this time).

Maybe this detailed exercise was too much for the boy, LOL - as it turns out, he decided on a journalism major and he's doing OK with it (had a few articles published in his college paper and in a few local newspapers). But he's no longer interested in building the "tin-can gun", as he calls it. I was cleaning out some of my drawing files on the computer tonight and came across our drawing - I thought that it might be of interest here from the aspect of a machining challenge. So here's the drawing and the preliminary stress analysis - for ENTERTAINMENT only - that we came up with:

The stress/deformation analysis was made only for the receiver. I made the assumption that it would be the weakest link in the design.

Note that the "tin-can gun" was never made; it would have been a good project to photo-document because there are a number of challenging operations involved, not only machining but hardening, grinding, stress-relieving and a LOT of hand-fitting of small parts.