- Joined

- Nov 13, 2012

- Messages

- 175

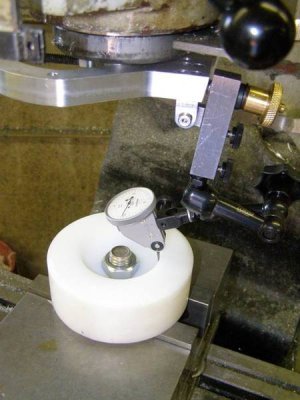

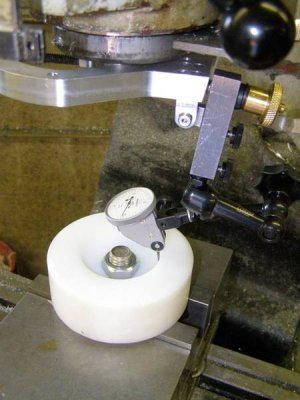

We have a thread for over the counter measuring tools, so how about one for shop made measuring tools.

I often end up in situation where I don't have the correct tool, or the tool doesn't exist, or the existing tool is less than satisfactory. So I end up making or modifying a tool for the task. So show us what you've made or modified. Measuring related tools only, please.

I often end up in situation where I don't have the correct tool, or the tool doesn't exist, or the existing tool is less than satisfactory. So I end up making or modifying a tool for the task. So show us what you've made or modified. Measuring related tools only, please.