- Joined

- Sep 19, 2012

- Messages

- 3,063

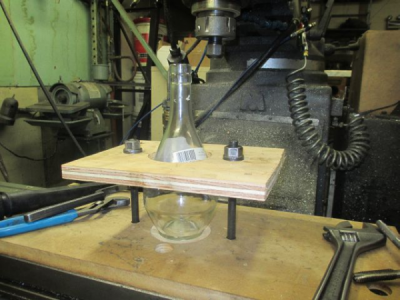

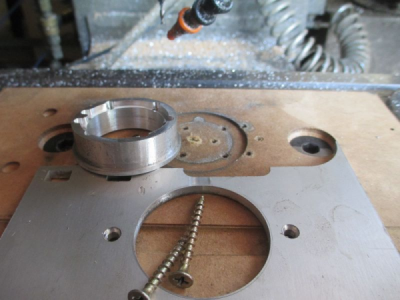

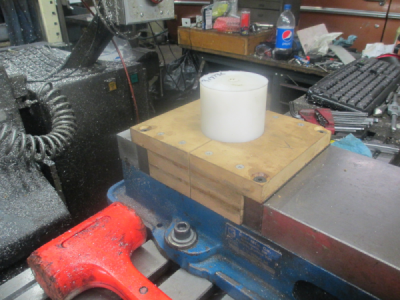

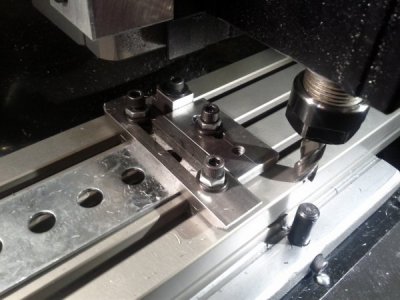

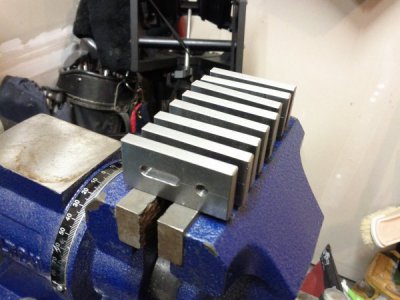

Ok... let's see your shop made hold downs and clamps! Anything you made special for a specific job to everyday clamps. From fit and pretty to quick and ugly, don't be shy!

Sent from somwhere in east Texas by Jake!

Sent from somwhere in east Texas by Jake!