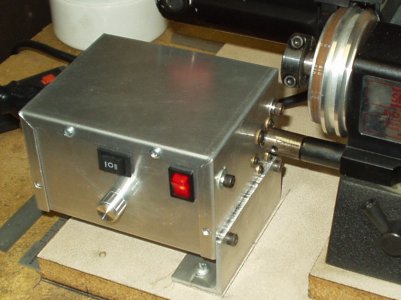

Going to explain what I've done as far as a power feed for my Sherline lathe. I know this won't be for everyone, but it works fairly well for me. After using the power feed Sherline sold, I knew I wanted more speed and the added features of variable speed, as well as reverse. I settled on a small 300 RPM gear motor I found on eBay. I found a variable speed reversible controller on Amazon, a 12 VDC wall wart that had enough amperage to work with the electronics, and an aluminum enclosure. Total cost at that point was under $50. When assembled and used, it was easy to see the trade-off between speed and torque. I could stop the advance of the saddle with my finger when moving at a reasonable cutting speed. Tried a 200 RPM motor. Better, but still lacking in power for some cuts. Next was a motor that has an output of 30 RPM. The torque was there, but the speed was too similar to the Sherline unit. I finally settled on a 100 RPM motor and have been using that with a fair amount of success for what I do on the lathe. Not exactly a speed demon, but still five times faster than the Sherline version of a power feed. All the gear motors I tried have the same size bolt pattern on the mounting end and I added an aluminum plate to the inside of the "wall" where the motor mounts for strength. There was no way the soft aluminum enclosure was going to be able to support the weight of whichever motor was in use. The plate also strengthens the box where the mounting bracket is attached. When I first tried to stuff everything into the enclosure, I didn't have room for the power adapter, so I cut it open to see if it could be altered to fit. I was surprised to see just how little actual hardware there was inside the plastic shell. Anyway, I picked up a lighted power switch at a local hardware store, and added a power entry port like you find on computers. The last thing I had to do was make an adapter from the motor shaft to the lathe shaft. Okay then, I hope my explanation wasn't too random.