I need to make some special knife pivot screws that are 64 TPI. I successfully ground a threading tool in HSS for the mini lathe. Now I have a larger lathe with 1" square tool holders. The external and internal threading insert tools only go down to 48 TPI. I am sure that has to do with the radius ground at the tip.

My question is, can I take one of these cutters made for 48 TPI and sharpen it more so I can make the 64 TPI threads? This would be my preferred solution so I do not have to mess with shims and such each time changing out a tip.

Or, would it be better to make a 1" shank tool holder to hold the hand ground HSS 1/4" tools (made from 1/4" blanks) I know I can make?

Or, maybe someone already makes something like this?

Thanks!

Eric

My question is, can I take one of these cutters made for 48 TPI and sharpen it more so I can make the 64 TPI threads? This would be my preferred solution so I do not have to mess with shims and such each time changing out a tip.

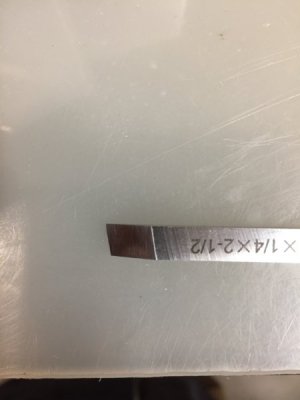

Or, would it be better to make a 1" shank tool holder to hold the hand ground HSS 1/4" tools (made from 1/4" blanks) I know I can make?

Or, maybe someone already makes something like this?

Thanks!

Eric