- Joined

- Mar 21, 2013

- Messages

- 4,063

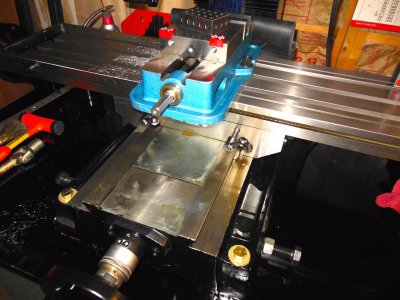

Bill congrats on making chips! Too bad about the Y way, any chance it came off the vice or something else? Bah it will make a nice oil reservoir happy milling!

I'm thinking it was a iron shaving in the Y-axis gibb area. It made a shallow gouge in the base way and made a black powder streak down the way. I stoned it out and yea you're right, it will make a nice little oil galley. I will pull the gibb strips for the x and y axis' tomorrow and squirt some brake cleaner or something in there to flush the area out.