- Joined

- Mar 21, 2013

- Messages

- 4,120

Well, today I spent a few more hours with the mill.

Jon: I measured my table and the slots are like .645 which is 20 thou over 5/8". I think (hope?) I'll be fine with the clamping kit when it arrives.

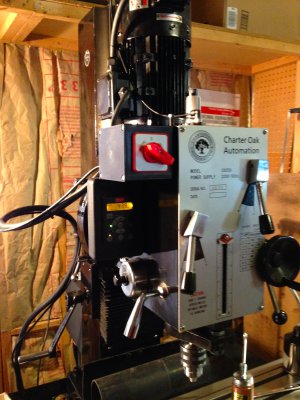

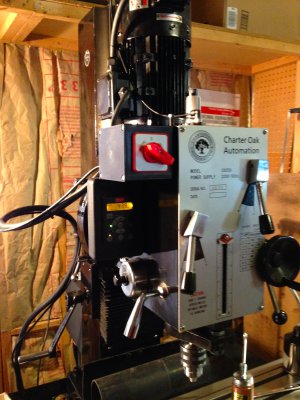

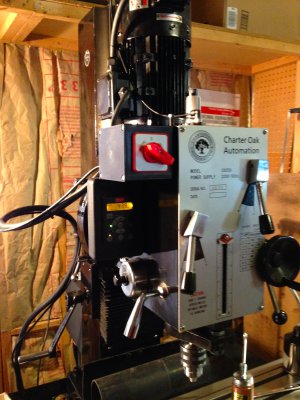

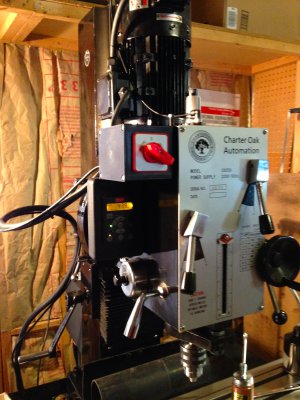

I got him leveled, adjusted the gibbs ever so slightly, put the plug on the power cord (and connected the RS485 cable from the VFD front panel) and fired it up. Very nice, and not too noisy although if I had to listen to this for any length of time above 3k rpm it might start to grate. The pulley conversion kit should fix that though. The electric fan on the motor and the VFD make almost as much noise as the head does.

Question for those with VFDs? The digital display reads from 0-50 (which is full speed) is this indicative of the frequency/Hz? It seems to be happiest above 30 or so. Do most of you just tweak the frequency for chatter/finish? Sorry, this is my first VFD and haven't any experience with them.

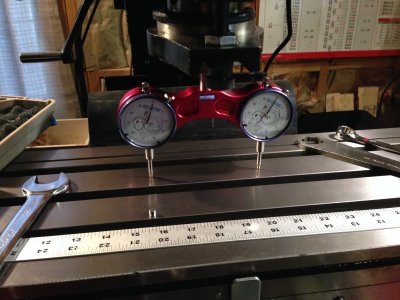

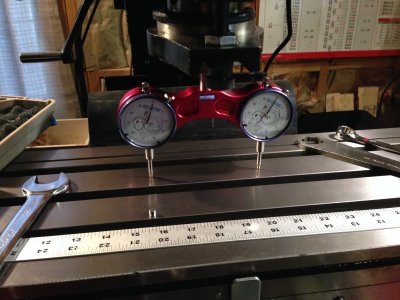

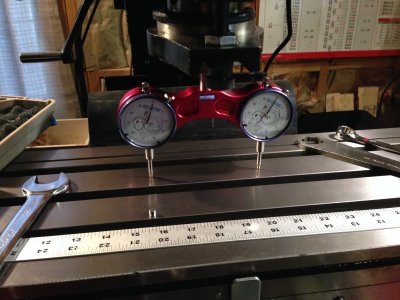

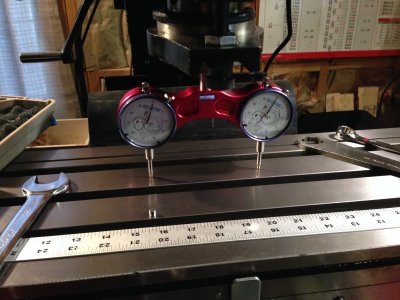

I checked tram and didn't have to touch anything. X-axis is dead on and Y-axis is less than a half-thou across 6". Close enough for my purposes.

I don't like the idea of having to plug/unplug this thing every time I use it, and these plug/receptacles are not designed for it and will wear. Guess I may have to have the electrician back out to put a switch on this thing. Or something. Electrical isn't my forte.

The other nag is that I got really used to (and spoiled by) being able to just take a step back and reach down into a drawer for all my cutters, collets, rotary table, etc.. With this setup I have to walk over to Blue's tool box every time I need something. It's already getting old. I have a friend that likes to work with wood and I was thinking that I may ask his opinion about making some drawers for the mill stand. That would be kinda cool.

As we all like pics around here, I've included a few for your perusal. )

)

Left side of the head showing the VFD remote

I'd say the tram is close enough.

Oh, and I was lucky enough to find someone here on the board who was selling a Kurt 5".

Shop is getting messy again...

Jon: I measured my table and the slots are like .645 which is 20 thou over 5/8". I think (hope?) I'll be fine with the clamping kit when it arrives.

I got him leveled, adjusted the gibbs ever so slightly, put the plug on the power cord (and connected the RS485 cable from the VFD front panel) and fired it up. Very nice, and not too noisy although if I had to listen to this for any length of time above 3k rpm it might start to grate. The pulley conversion kit should fix that though. The electric fan on the motor and the VFD make almost as much noise as the head does.

Question for those with VFDs? The digital display reads from 0-50 (which is full speed) is this indicative of the frequency/Hz? It seems to be happiest above 30 or so. Do most of you just tweak the frequency for chatter/finish? Sorry, this is my first VFD and haven't any experience with them.

I checked tram and didn't have to touch anything. X-axis is dead on and Y-axis is less than a half-thou across 6". Close enough for my purposes.

I don't like the idea of having to plug/unplug this thing every time I use it, and these plug/receptacles are not designed for it and will wear. Guess I may have to have the electrician back out to put a switch on this thing. Or something. Electrical isn't my forte.

The other nag is that I got really used to (and spoiled by) being able to just take a step back and reach down into a drawer for all my cutters, collets, rotary table, etc.. With this setup I have to walk over to Blue's tool box every time I need something. It's already getting old. I have a friend that likes to work with wood and I was thinking that I may ask his opinion about making some drawers for the mill stand. That would be kinda cool.

As we all like pics around here, I've included a few for your perusal.

Left side of the head showing the VFD remote

I'd say the tram is close enough.

Oh, and I was lucky enough to find someone here on the board who was selling a Kurt 5".

Shop is getting messy again...