- Joined

- Apr 12, 2013

- Messages

- 562

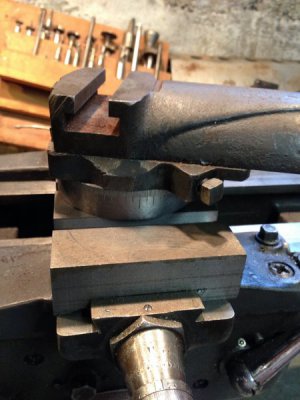

One hitch I have found in using my new A-11 cross slide. It does not have any easy way that I can see to implement a protractor without adding more height, and the standard Atlas compound doesn't have a nice flat face for a handheld protractor. The top of the slide is already a quarter inch or more taller than the standard slide, and I don't want to lose any more clearance if I can avoid it, so something under the compound is not preferred. It would have to be very thin, and keyed to a slot or the face of the slide to work anyway.

So how do I set the 30 degree angle for threading, or will I have to switch back to the standard Atlas slide for this?

One thing I was able to do is scribe a line perpendicular to the ways, so I have a nice zero reference. I just can't figure out how to get a protractor from the edge of the slide to the compound to set an angle for threading.

So how do I set the 30 degree angle for threading, or will I have to switch back to the standard Atlas slide for this?

One thing I was able to do is scribe a line perpendicular to the ways, so I have a nice zero reference. I just can't figure out how to get a protractor from the edge of the slide to the compound to set an angle for threading.