- Joined

- Nov 13, 2012

- Messages

- 49

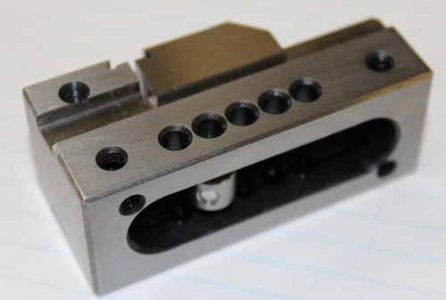

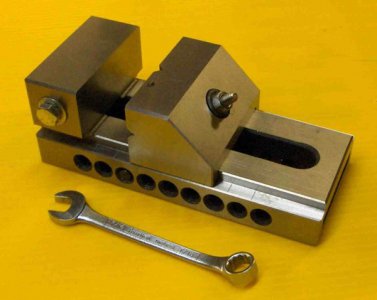

Looking for opinions on the small screwless precision vises.

I've looked at various sizes on Ebay and Amazon, along with Shar's and a few other suppliers.

What are your all's thoughts on the "asian" made vises? I am looking for a 2" or 3" sized vise. Something small enough to also attach to my rotary table for an occasional project.

I don't have any plans to try and work in .0001" tolerances at this point. I'm just looking for something smaller and fairly accurate. Most ads are claiming the vises are "precision" ground to within .0002" tolerances. Of course, we all know how true that statement can be...

Thanks in advance,

Jeff in Hagerstown

I've looked at various sizes on Ebay and Amazon, along with Shar's and a few other suppliers.

What are your all's thoughts on the "asian" made vises? I am looking for a 2" or 3" sized vise. Something small enough to also attach to my rotary table for an occasional project.

I don't have any plans to try and work in .0001" tolerances at this point. I'm just looking for something smaller and fairly accurate. Most ads are claiming the vises are "precision" ground to within .0002" tolerances. Of course, we all know how true that statement can be...

Thanks in advance,

Jeff in Hagerstown