- Joined

- Dec 23, 2016

- Messages

- 33

hello!

My first problem to put to you lot!

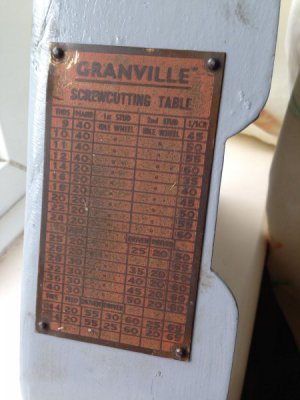

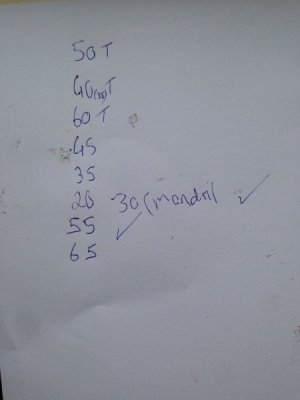

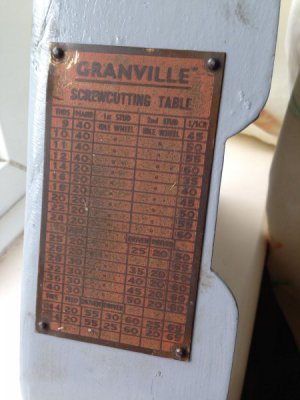

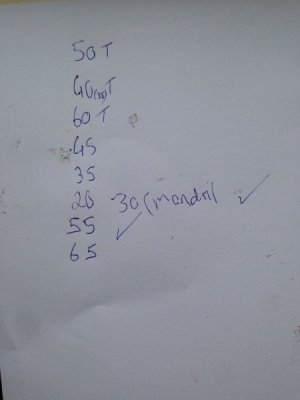

Basically my old Granville lathe has some of its gears missing, sourcing them is not as problem as the myford gears fit. My problem is which ones do I need?

Iv attached 2 pictures, 1 is a list of gears which I have, the other is the screw cutting table on the machine.

hello!

hello!

My first problem to put to you lot!

Basically my old Granville lathe has some of its gears missing, sourcing them is not as problem as the myford gears fit. My problem is which ones do I need?

Iv attached 2 pictures, 1 is a list of gears which I have, the other is the screw cutting table on the machine. Can anyone confirm which ones I need to get?

Also, the table shows for the 1st and second stud just " can't work out what that's telling me!

This is the first time iv had any experience on a lathe without a quick change gear box so any help is much appreciated!

Thanks!!

Jack

My first problem to put to you lot!

Basically my old Granville lathe has some of its gears missing, sourcing them is not as problem as the myford gears fit. My problem is which ones do I need?

Iv attached 2 pictures, 1 is a list of gears which I have, the other is the screw cutting table on the machine.

hello!

hello!My first problem to put to you lot!

Basically my old Granville lathe has some of its gears missing, sourcing them is not as problem as the myford gears fit. My problem is which ones do I need?

Iv attached 2 pictures, 1 is a list of gears which I have, the other is the screw cutting table on the machine. Can anyone confirm which ones I need to get?

Also, the table shows for the 1st and second stud just " can't work out what that's telling me!

This is the first time iv had any experience on a lathe without a quick change gear box so any help is much appreciated!

Thanks!!

Jack

its hard to explain unless you are in person to show how its done. South bend lathe has a book on line how to run a lathe that has a good explanation.

its hard to explain unless you are in person to show how its done. South bend lathe has a book on line how to run a lathe that has a good explanation.