-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scratch Built CNC Micro Slant Bed Lathe

- Thread starter shooter123456

- Start date

- Joined

- Apr 28, 2014

- Messages

- 3,590

Wow...

- Joined

- Jan 20, 2016

- Messages

- 602

Wow time flies!

I have been trying to figure out the issue with noise from the spindle motor. I am not sure if it is the motor or the drive that is causing the problem.

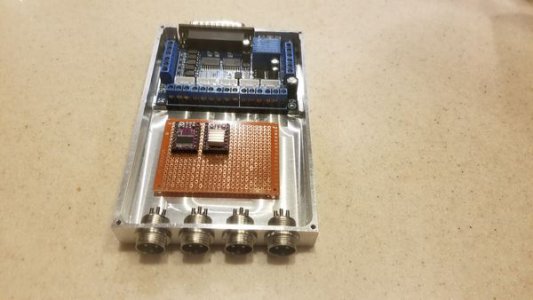

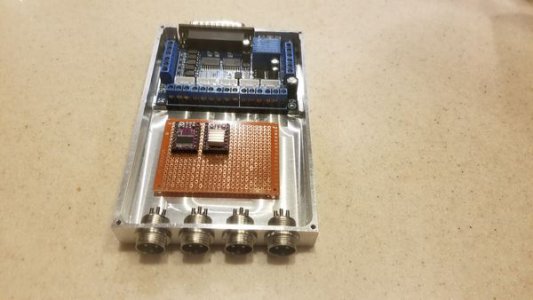

The first thing I am doing to address the issue is making an electronics box to case up the control electronics and I will ground the box to hopefully shield everything inside from the outside noise. I will also be cutting the stepper wires down and replacing them with shielded wire. Then I will try swapping the spindle motor wires for shielded wire as well, and try to move the control electronics as physically far from the spindle motor and electronics as I can. Fingers crossed that that solves it.

Here are some pictures of the box. I haven't wired and soldered everything up yet. I am waiting for the last stepper driver to arrive before I do that because once I solder everything in, it may be a pain in the butt to get it out.

As for the turret, I am a bit stumped at the moment. I can't seem to wrap my head around the racheting mechanism I was planning to use. I am starting to consider using a pneumatic cylinder instead to lock everything in place. I ordered all the parts to make the racheting turret. So far, the parts and cost for it are:

6003-2RS bearing - $2.88

6000-2RS bearing - $1.99

Nema 17 stepper motor - $13.90

Stepper driver - $1.60

Steel rod - $2

Aluminum stock - $5

Total so far - $27.37

Once I figure out what I will do and start machining it, I will post an update.

I have been trying to figure out the issue with noise from the spindle motor. I am not sure if it is the motor or the drive that is causing the problem.

The first thing I am doing to address the issue is making an electronics box to case up the control electronics and I will ground the box to hopefully shield everything inside from the outside noise. I will also be cutting the stepper wires down and replacing them with shielded wire. Then I will try swapping the spindle motor wires for shielded wire as well, and try to move the control electronics as physically far from the spindle motor and electronics as I can. Fingers crossed that that solves it.

Here are some pictures of the box. I haven't wired and soldered everything up yet. I am waiting for the last stepper driver to arrive before I do that because once I solder everything in, it may be a pain in the butt to get it out.

As for the turret, I am a bit stumped at the moment. I can't seem to wrap my head around the racheting mechanism I was planning to use. I am starting to consider using a pneumatic cylinder instead to lock everything in place. I ordered all the parts to make the racheting turret. So far, the parts and cost for it are:

6003-2RS bearing - $2.88

6000-2RS bearing - $1.99

Nema 17 stepper motor - $13.90

Stepper driver - $1.60

Steel rod - $2

Aluminum stock - $5

Total so far - $27.37

Once I figure out what I will do and start machining it, I will post an update.

If you don't mind some unsolicited advice, breakout boards like that have a tendency to self immolate, particularly in confided spaces. If you've got the vertical room, it'd be worth socketing them. That way you don't need to fiddle around with de-soldering on a perf board if one of them dies prematurely. 2.54mm pitch female headers are pretty inexpensive. Just a thought.

Awsome build,

Jake

Awsome build,

Jake

- Joined

- Jan 20, 2016

- Messages

- 602

Unsolicited advice is half the reason I post about what I am doing. I can't tell you how many hours of frustration I have saved by people offering tips exactly like this. I will see if I can fit some headers, at least for the parts that are worth saving if the board blows.If you don't mind some unsolicited advice, breakout boards like that have a tendency to self immolate, particularly in confided spaces. If you've got the vertical room, it'd be worth socketing them. That way you don't need to fiddle around with de-soldering on a perf board if one of them dies prematurely. 2.54mm pitch female headers are pretty inexpensive. Just a thought.

Awsome build,

Jake

The box will have a computer fan blowing air through to keep everything cool. Do you think thats enough to keep the board from burning up?

Thank you for your advice. It is much appreciated.

Most likely, the only components that are a real risk are the drivers themselves, and if you stay within their rated range current range and have airflow you should be fine. Mostly the the problem is the proliferation of counterfeit drivers, even from reliable suppliers, with degraded current/temperature ranges.

If you want to get a yes-no answer, the data sheets for the IC and heat sink will have thermal resistances and convective cooling coefficients. If you divide your fan's flow rate by the cross-sectional area of your box you will be able to work out roughly how hot each driver will get. (I don't actually recommend this except as an educational exercise).

Thanks for posting your work for the world, it's fun to see.

If you want to get a yes-no answer, the data sheets for the IC and heat sink will have thermal resistances and convective cooling coefficients. If you divide your fan's flow rate by the cross-sectional area of your box you will be able to work out roughly how hot each driver will get. (I don't actually recommend this except as an educational exercise).

Thanks for posting your work for the world, it's fun to see.