- Joined

- Jan 20, 2016

- Messages

- 602

A few months ago, I realized that I am constantly needing fasteners and other small parts that halt a project in its tracks. Everything from your regular 1/4x20 screws to things like M12x1 lock nuts. I spend a lot of time trying to find these, pay too much for them or buy them in large quantities, then spend more time cutting them to length. I started thinking about a small lathe that would be able to make fasteners for me so that I didn't need to stop projects when I am on a roll and wait a few days to order a fastener or search hardware stores for them. So I started drawing and doing a few simulations and pricing things out and I think I came up with something that will work.

My requirements were:

-Single point threading in steel

-Turn at least 1" in diameter

-$250 or less

-Make a 3/8x16x1" socket head screw in 4 minutes

For the spindle, I am using 2 deep groove ball bearings, an aluminum housing, and a faceplate to mount a custom chuck. I haven't decided what kind of chuck I will use, but it will probably be an ER collet system. For the spindle motor, again not decided but I have been thinking about using a Nema 34 stepper. It isn't the ideal solution, but using a 3:1 pulley, I should be able to get enough speed and torque out of it and threading will be easy at low speeds.

Linear motion for the Z axis will be on a Rexroth 25mm linear rail I got for $30 shipped on eBay. It is 9.25" long and will give me roughly 5.5" of travel. It will use a Nema 23 stepper and an acme lead screw for motion. I want to make one from 12L14 just because I haven't done any acme threading before, but I may just buy ground leadscrew stock and make it with that.

The X axis is still up in the air. I haven't been able to find a pair of small linear rails for a decent price. I will keep looking though. It will either use a Nema 17 stepper or a smaller Nema 23. I will use a leadscrew on the X as well.

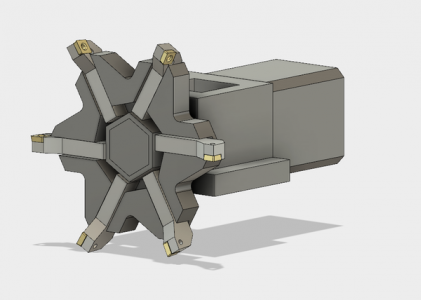

I don't need fast rapids for this machine since it will only have about 5" of Z travel and 3.5-5" of X travel. Cutting at 10 IPM with .01" coming off per pass, the 3/8x16x1" screw will need 10 passes to turn it down to thread size, each pass will take 6 seconds, so that will be about 1 minute 30 seconds to turn it to the right diameter. This leaves me 2 minutes 30 seconds for the threading and parting to meet my goal. I am either going to use some kind of gang tooling or a turret for tool changing. I haven't decided entirely yet.

So far my costs and estimated costs are:

I already have

-Spindle bearings - $20

-Z linear rail - $30

-Various stock - $15

-Thrust bearings - $10

Estimated costs to come

-Spindle motor - $40

-Z axis motor - $20

-X axis motor - $15

-X axis rails - $30

-Z axis leadscrew - $5

-X axis leadscrew - $5

-Power supply - $20

-Spindle motor driver - $30

-Z axis driver - $15

-X axis driver - $10

-Breakout board - $10

Motor for tool changer - $15

Driver for tool changer - $5

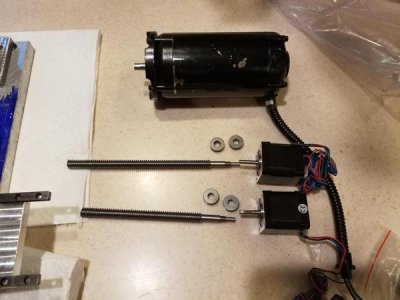

This has me a bit over budget, but my initial budget didn't include the tool changer. To get the budget reduced, I have a few ideas. First is with the spindle motor. I might pick up a treadmill for $20 or less and take the motor out of that. Then make an encoder. That would give me more power and cut the price down $50. I have also been thinking of using dovetails on the X axis instead of rails. This will cut the cost by about $25.

Here are some pictures. I welcome questions, criticism and suggestions if anyone has some.

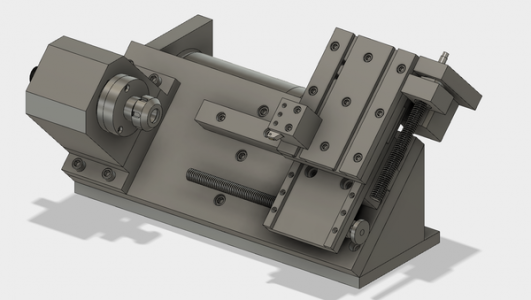

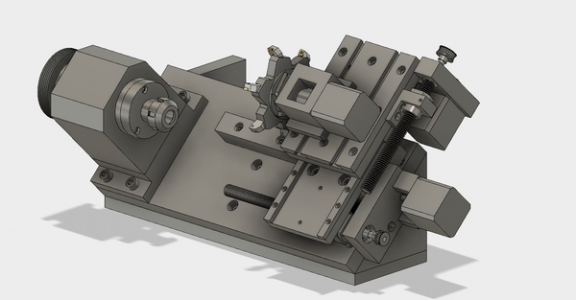

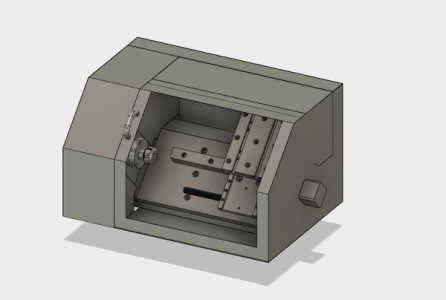

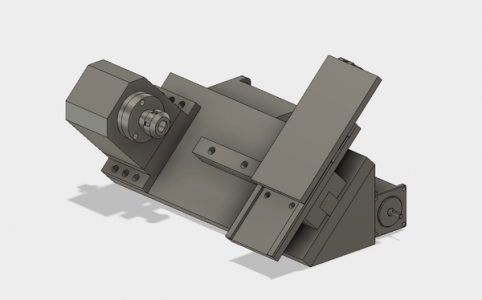

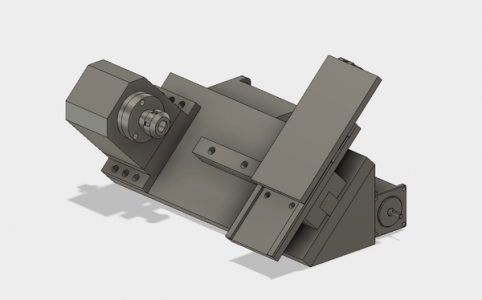

Here is the 3D model of the machine. It is about 14" long.

Here is the spindle machining in progress.

Here is the mostly complete spindle. That is a AAA battery for scale.

Bearings on the spindle.

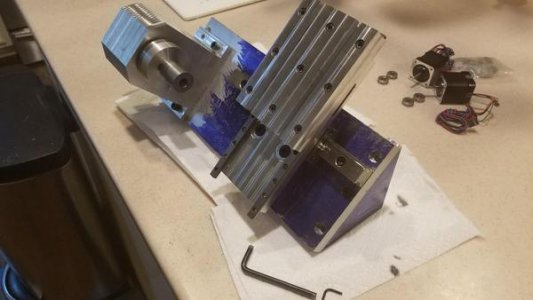

For the spindle housing, I JB welded 4 .75" pieces of aluminum together. They were cleaned thoroughly, degreased, and roughed up beforehand. They will secured to the base and the spindle bearings will squeeze them together. I am not worried about it pulling apart.

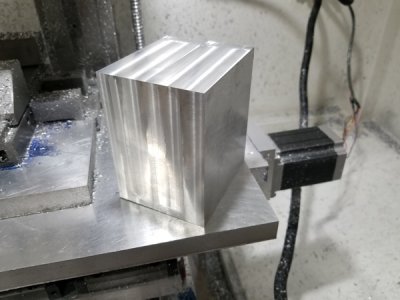

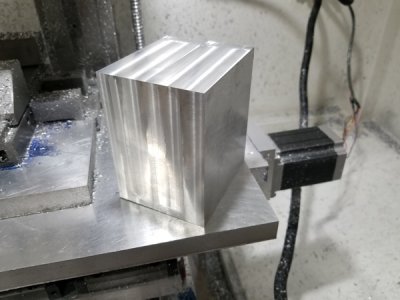

Then I squared it up on the mill.

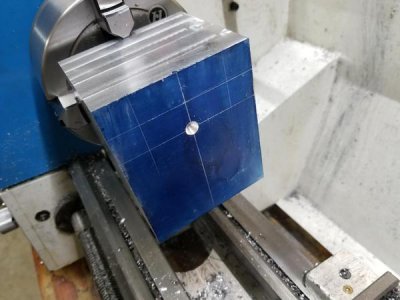

Then mounted in the lathe 4 jaw to do the majority of the boring for the spindle. That would have been a pain in the butt doing that on the mill.

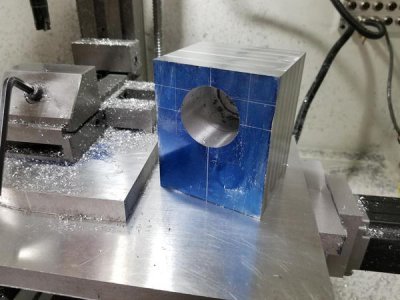

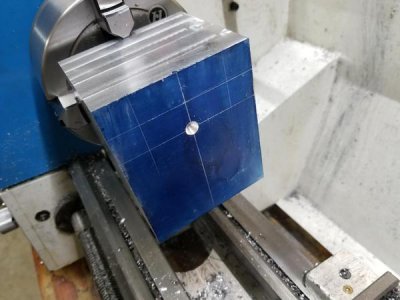

Here it is bored out before I cut the bearing seats. I did that with the CNC and they both fit well. I indicated on the bottom each time so that they will be perfectly perpendicular to the bottom.

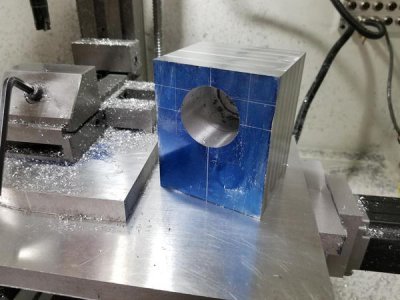

Bearings seats done and spindle base mostly machined. I just need to drill the holes for the screws to mount it to the table.

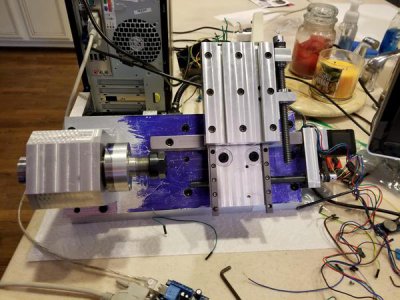

Here is where it is now. pardon the mess, I was cleaning a set of nasty linear rails I got online and went out to snap that picture really quick. Once I find some suitable rails or figure out dovetails for the X, I can press on.

My requirements were:

-Single point threading in steel

-Turn at least 1" in diameter

-$250 or less

-Make a 3/8x16x1" socket head screw in 4 minutes

For the spindle, I am using 2 deep groove ball bearings, an aluminum housing, and a faceplate to mount a custom chuck. I haven't decided what kind of chuck I will use, but it will probably be an ER collet system. For the spindle motor, again not decided but I have been thinking about using a Nema 34 stepper. It isn't the ideal solution, but using a 3:1 pulley, I should be able to get enough speed and torque out of it and threading will be easy at low speeds.

Linear motion for the Z axis will be on a Rexroth 25mm linear rail I got for $30 shipped on eBay. It is 9.25" long and will give me roughly 5.5" of travel. It will use a Nema 23 stepper and an acme lead screw for motion. I want to make one from 12L14 just because I haven't done any acme threading before, but I may just buy ground leadscrew stock and make it with that.

The X axis is still up in the air. I haven't been able to find a pair of small linear rails for a decent price. I will keep looking though. It will either use a Nema 17 stepper or a smaller Nema 23. I will use a leadscrew on the X as well.

I don't need fast rapids for this machine since it will only have about 5" of Z travel and 3.5-5" of X travel. Cutting at 10 IPM with .01" coming off per pass, the 3/8x16x1" screw will need 10 passes to turn it down to thread size, each pass will take 6 seconds, so that will be about 1 minute 30 seconds to turn it to the right diameter. This leaves me 2 minutes 30 seconds for the threading and parting to meet my goal. I am either going to use some kind of gang tooling or a turret for tool changing. I haven't decided entirely yet.

So far my costs and estimated costs are:

I already have

-Spindle bearings - $20

-Z linear rail - $30

-Various stock - $15

-Thrust bearings - $10

Estimated costs to come

-Spindle motor - $40

-Z axis motor - $20

-X axis motor - $15

-X axis rails - $30

-Z axis leadscrew - $5

-X axis leadscrew - $5

-Power supply - $20

-Spindle motor driver - $30

-Z axis driver - $15

-X axis driver - $10

-Breakout board - $10

Motor for tool changer - $15

Driver for tool changer - $5

This has me a bit over budget, but my initial budget didn't include the tool changer. To get the budget reduced, I have a few ideas. First is with the spindle motor. I might pick up a treadmill for $20 or less and take the motor out of that. Then make an encoder. That would give me more power and cut the price down $50. I have also been thinking of using dovetails on the X axis instead of rails. This will cut the cost by about $25.

Here are some pictures. I welcome questions, criticism and suggestions if anyone has some.

Here is the 3D model of the machine. It is about 14" long.

Here is the spindle machining in progress.

Here is the mostly complete spindle. That is a AAA battery for scale.

Bearings on the spindle.

For the spindle housing, I JB welded 4 .75" pieces of aluminum together. They were cleaned thoroughly, degreased, and roughed up beforehand. They will secured to the base and the spindle bearings will squeeze them together. I am not worried about it pulling apart.

Then I squared it up on the mill.

Then mounted in the lathe 4 jaw to do the majority of the boring for the spindle. That would have been a pain in the butt doing that on the mill.

Here it is bored out before I cut the bearing seats. I did that with the CNC and they both fit well. I indicated on the bottom each time so that they will be perfectly perpendicular to the bottom.

Bearings seats done and spindle base mostly machined. I just need to drill the holes for the screws to mount it to the table.

Here is where it is now. pardon the mess, I was cleaning a set of nasty linear rails I got online and went out to snap that picture really quick. Once I find some suitable rails or figure out dovetails for the X, I can press on.