- Joined

- May 7, 2014

- Messages

- 776

Well the post should really be titled "How I spent my Summer Vacation". I'll see if the Misses can forgive my chronic toydum' over the summer of 2016 and do something nice to her craft room over Winter! -Pay'n the piper on this one guys!

Issue 1: My S45 Machine Torch (from Everlast) went belly-up. It simply would not stay running. I knew it was the head assy. To get a new Head piece was going to be $170+shipping.

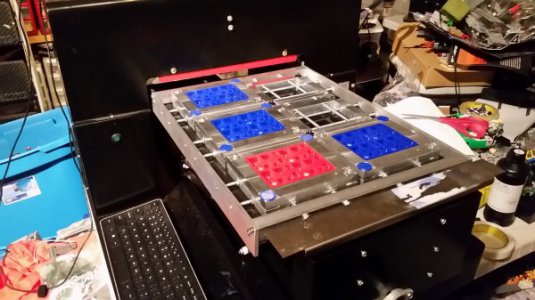

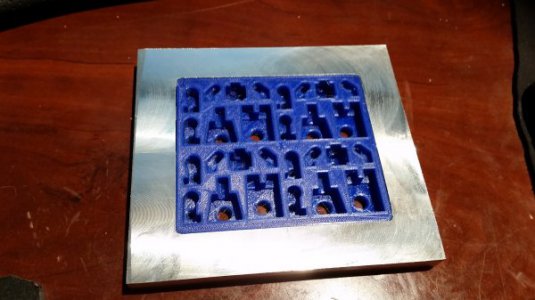

Item 1: My Son talked me into a new 3D printer for the shop! And it's a dandy! I used it to fix my DoAll power down feed geared head Drill not long ago. (on another thread).

Item 2: I have been dying to get away from Draftsight and into Fusion360! A 3D CAD program w/ built in CAM support and 3D printer compatibility. It's just amazing!

Mix that all together a few months back and you get the Video below:

This Machine torch goes with my first ever CNC end to end Milling project which is the torch holder in the pics. I did a write up here: http://www.hobby-machinist.com/thre...ct-is-done-thanks-to-hmers.39980/#post-348838

A few pics of the unit all buttoned up and a short test cut run. NOT dialed in. Just tossed something up. Just proved we're operational again! Whew!

... thumbnails- click to open.

A few final comments:

The video printing our part is about 3 printed parts into the total of probably 15 or so we actually printed out! things like 3D settings, blocking, layer adhesion/temp, Wow- We learned so much about 3D printing (My son and I). We're excited on the way it supplements our budding shop. The Speed at which Fusion360 can crank out a part, and the overall element of DIY!

Lessons learned:

- Expect to design the part quickly. Fusion360 (never touched it before) and I had the basic 3D render done in about a day. After that it was learning all the extra elements for making it into a real functional part with trial and error prints out and finding out it needs this or that moved and tweaked.

-Nothing is fast in 3D printing. Each side takes 3.5 hours. We did just upgrade to simply3D rather than Cura and that runs about 1.5hours w/ some special gCode optimizing and material fill-in algo's.

- Use Goggle ChromeCast- Setup my Lappy to the 55" TV and use YouTube to watch the Fusion360 channel from Autodesk on a big screen. In the space of about 2hours of videos, I then had my part ready in less than a day.

- I have found the NY-CNC youtube channel full of info on the use of Fusion360 and the CAM functionality. I'm told autodesk bought HSMWorks (hope I have that right) and integrated it into the CAM of F360? Either way- the NYCNC host loves it and had sold me on it. Will be making 2 more CNC machine torch holders & heads w/ my Son for his school w/F360 CAM replacing DolphinCAM.

Not sure if folks consider the 3D realm as valid HM forum material, but since it's tied in w/ my DIY torch kit and the ability to aid and assist our home shop of machines, how can we not welcome this tech w/ some really wide open arms!

Enjoy the coming Fall! I'm now behind on a few things but my torch is up and running and Fusion360 is our devoted CAD and CAM tool going into late 2016. Just cannot beat this one.

Jeff and Mitch.

Issue 1: My S45 Machine Torch (from Everlast) went belly-up. It simply would not stay running. I knew it was the head assy. To get a new Head piece was going to be $170+shipping.

Item 1: My Son talked me into a new 3D printer for the shop! And it's a dandy! I used it to fix my DoAll power down feed geared head Drill not long ago. (on another thread).

Item 2: I have been dying to get away from Draftsight and into Fusion360! A 3D CAD program w/ built in CAM support and 3D printer compatibility. It's just amazing!

Mix that all together a few months back and you get the Video below:

This Machine torch goes with my first ever CNC end to end Milling project which is the torch holder in the pics. I did a write up here: http://www.hobby-machinist.com/thre...ct-is-done-thanks-to-hmers.39980/#post-348838

A few pics of the unit all buttoned up and a short test cut run. NOT dialed in. Just tossed something up. Just proved we're operational again! Whew!

... thumbnails- click to open.

A few final comments:

The video printing our part is about 3 printed parts into the total of probably 15 or so we actually printed out! things like 3D settings, blocking, layer adhesion/temp, Wow- We learned so much about 3D printing (My son and I). We're excited on the way it supplements our budding shop. The Speed at which Fusion360 can crank out a part, and the overall element of DIY!

Lessons learned:

- Expect to design the part quickly. Fusion360 (never touched it before) and I had the basic 3D render done in about a day. After that it was learning all the extra elements for making it into a real functional part with trial and error prints out and finding out it needs this or that moved and tweaked.

-Nothing is fast in 3D printing. Each side takes 3.5 hours. We did just upgrade to simply3D rather than Cura and that runs about 1.5hours w/ some special gCode optimizing and material fill-in algo's.

- Use Goggle ChromeCast- Setup my Lappy to the 55" TV and use YouTube to watch the Fusion360 channel from Autodesk on a big screen. In the space of about 2hours of videos, I then had my part ready in less than a day.

- I have found the NY-CNC youtube channel full of info on the use of Fusion360 and the CAM functionality. I'm told autodesk bought HSMWorks (hope I have that right) and integrated it into the CAM of F360? Either way- the NYCNC host loves it and had sold me on it. Will be making 2 more CNC machine torch holders & heads w/ my Son for his school w/F360 CAM replacing DolphinCAM.

Not sure if folks consider the 3D realm as valid HM forum material, but since it's tied in w/ my DIY torch kit and the ability to aid and assist our home shop of machines, how can we not welcome this tech w/ some really wide open arms!

Enjoy the coming Fall! I'm now behind on a few things but my torch is up and running and Fusion360 is our devoted CAD and CAM tool going into late 2016. Just cannot beat this one.

Jeff and Mitch.

Last edited: