I'm curious what company you went with. I think I could swap parts/spindles on a head like that. I think you got a good deal and the fact that they are willing to help you is outstanding.

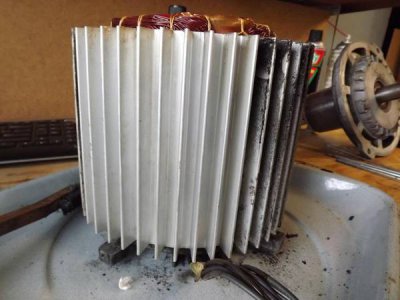

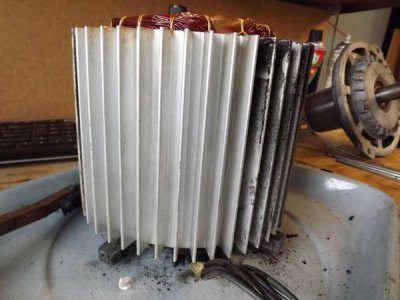

Central Penn Machinery is the name of the place, out of Lebanon, PA. I can't complain too much, I paid $799 for the head which is about half (or less) what they normally go for. If it weren't for them blasting water into it, I'd be perfectly happy with what I've found so far. For that price I expected a functional head that needed a rebuild (which the upper head does need). The spindle is beautiful on it actually, though I may change it out for the R8 spindle from the Long Chang head (same bearings/same length/same splines) just to get cheaper tooling. Haven't made up my mind for sure yet (and I already have a new spindle bearing set if I decide to do that). Also unfortunate, the parts from the feed reverse/feed worm shaft were messed up on the LC head too, so they're of no use.