- Joined

- Apr 30, 2012

- Messages

- 2,401

Re: zx45 milling machine cnc conversion

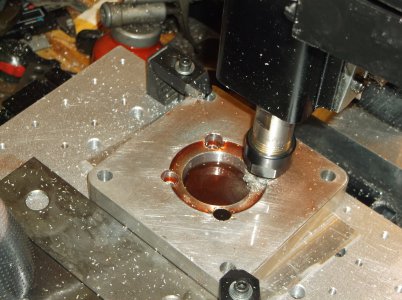

here are a few of the parts i have made for the z axis ballscrew upper bearing mount

it would be done but i made a mistake on the endcap offset in the g-code it centered on the line instead of being on the inside and so i get to make another

thats what scrap bins are for. premachined parts for future projects

steve

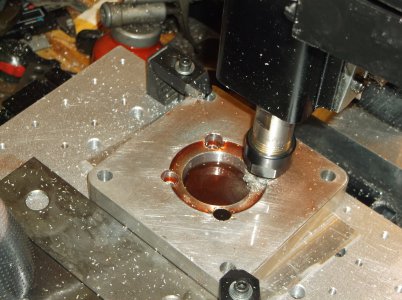

here are a few of the parts i have made for the z axis ballscrew upper bearing mount

it would be done but i made a mistake on the endcap offset in the g-code it centered on the line instead of being on the inside and so i get to make another

thats what scrap bins are for. premachined parts for future projects

steve