- Joined

- Apr 30, 2012

- Messages

- 2,401

Re: zx45 milling machine cnc conversion

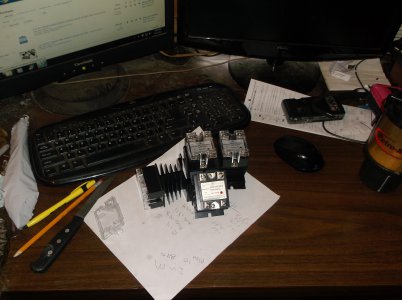

I got all the low voltage for the rear panel done. motor connectors ( 4 ), coolant pump control, limit switch, spindle control the only low volt wiring on the front panel is the e-stop no and nc connections. I also ran wires to the relay and the two remaining input terminals on the breakout board to the main panel to make them easier to get to if needed in the future. right now i'm just wiring spindle for an on/off relay.

I got all the low voltage for the rear panel done. motor connectors ( 4 ), coolant pump control, limit switch, spindle control the only low volt wiring on the front panel is the e-stop no and nc connections. I also ran wires to the relay and the two remaining input terminals on the breakout board to the main panel to make them easier to get to if needed in the future. right now i'm just wiring spindle for an on/off relay.