- Joined

- May 19, 2016

- Messages

- 13

Well guys here is my first post,

I have a BP mill, J head, which is in need of some head rebuilding, (bearing going out,I think,

and I am looking for a good place to sent it for a check out/rebuild etc,

on the West coast if possible, so I can't use it at this time.

I have my eye on a Grizzy 0755 mill as a second mill, until I can get it.

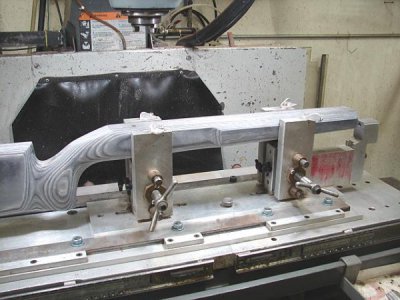

For now, I have to use the router to hog out a couple of Blue laminated blanks for rear grip pistols actions,

for the bbl channel and action inletting etc.

Some where I seen a jig info, but can't find it now that I need that info,

that hold the blanks and allows the router to cut what is needed.

Does any member have any ideas/solutions on a jig of this type,

or where to find info on this jig?

The Dremel tool just not cut it with this laminate stuff.

Tia,

Don

I have a BP mill, J head, which is in need of some head rebuilding, (bearing going out,I think,

and I am looking for a good place to sent it for a check out/rebuild etc,

on the West coast if possible, so I can't use it at this time.

I have my eye on a Grizzy 0755 mill as a second mill, until I can get it.

For now, I have to use the router to hog out a couple of Blue laminated blanks for rear grip pistols actions,

for the bbl channel and action inletting etc.

Some where I seen a jig info, but can't find it now that I need that info,

that hold the blanks and allows the router to cut what is needed.

Does any member have any ideas/solutions on a jig of this type,

or where to find info on this jig?

The Dremel tool just not cut it with this laminate stuff.

Tia,

Don