- Joined

- Jan 1, 2014

- Messages

- 233

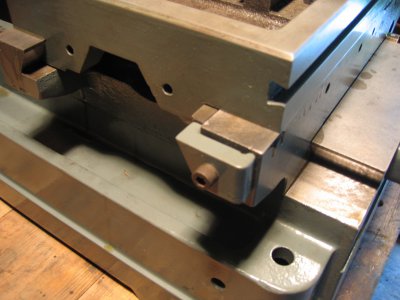

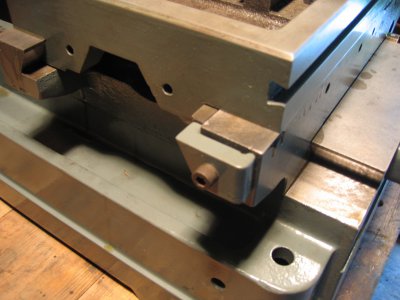

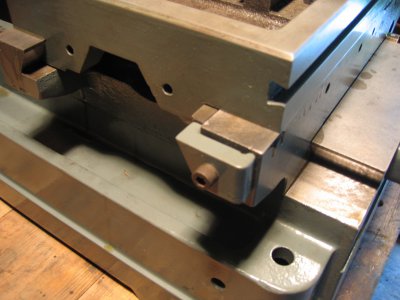

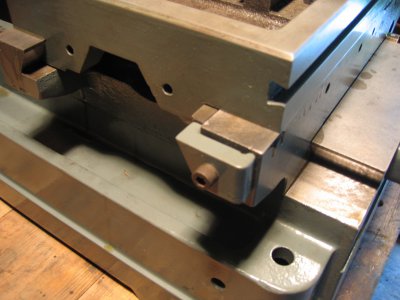

During the rebuild of my King round column bench mill, I noted that the gibs could only be adjusted so much before they would occasionally "tighten up" when the Y in particular, was moved back and forth. To alleviate this problem I drilled and tapped holes adjacent to the dovetail at the back end of each gib for a locking screw. In the case of the Y axis, the end of the gib was proud of the casting, so it was just a matter of turning a custom jam screw in my lathe with the biggest head that would fit. On the X axis, the gib end was buried, so I made a bracket to reach in to contact the back end of the gib with an associated cap screw. The gibs can now be set and locked which allows setting the gibs as tight as possible consistent with smooth travel of the X and Y.

Comments welcomed.

Comments welcomed.