- Joined

- Dec 6, 2012

- Messages

- 2,677

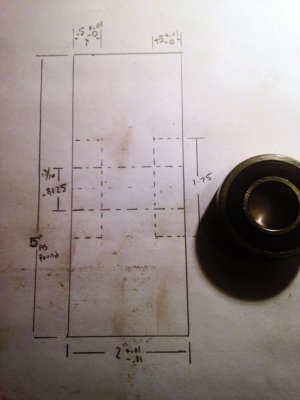

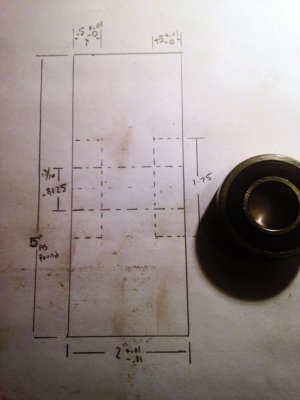

I've been asked to make 4 steel wheels for the city.

Their original spec was 5inch wheels with .5inch grade 8 axles/bolts on sealed bearings.

Something about using it to haul stuff from the garage to the ice rink for the Zamboni. It's unclear how much they plan on loading onto this little cart. Somewhere between several hundred and several thousand over occasionally irregular surfaces (read occasional impacts). We won't talk about if a rubber tire is more appropriate. Regardless slow speeds... very slow. I talked them into moving up to a .75inch grade 8 shaft and a larger bearing.

My question: What should the OD for the bearing be?

I've been studying the Machinerys Handbook and can't find the answer. Likely a user error....

Perhaps I'm overthinking this...

To tight and I potentially crimp the bearing preventing the axle from turning. To loose and I'll get bearing creep. Yet the two bearings need to align so that the axle spins. What do I need for tolerances for all these factors?

Truth is my question is multi fold: 1) what are my tolerances, 2) where could I have found this in the MH. I've read about press fits and bearings. ANSI, British and Metric. Lots of cool stuff. Just can't find the answer to the confusion. Please feel free to be critical my entire thinking of the problem and by drawing (other than it's not in CAD ).

).

Thank you,

Daryl

MN

Their original spec was 5inch wheels with .5inch grade 8 axles/bolts on sealed bearings.

Something about using it to haul stuff from the garage to the ice rink for the Zamboni. It's unclear how much they plan on loading onto this little cart. Somewhere between several hundred and several thousand over occasionally irregular surfaces (read occasional impacts). We won't talk about if a rubber tire is more appropriate. Regardless slow speeds... very slow. I talked them into moving up to a .75inch grade 8 shaft and a larger bearing.

My question: What should the OD for the bearing be?

I've been studying the Machinerys Handbook and can't find the answer. Likely a user error....

Perhaps I'm overthinking this...

To tight and I potentially crimp the bearing preventing the axle from turning. To loose and I'll get bearing creep. Yet the two bearings need to align so that the axle spins. What do I need for tolerances for all these factors?

Truth is my question is multi fold: 1) what are my tolerances, 2) where could I have found this in the MH. I've read about press fits and bearings. ANSI, British and Metric. Lots of cool stuff. Just can't find the answer to the confusion. Please feel free to be critical my entire thinking of the problem and by drawing (other than it's not in CAD

Thank you,

Daryl

MN