- Joined

- Apr 29, 2023

- Messages

- 11

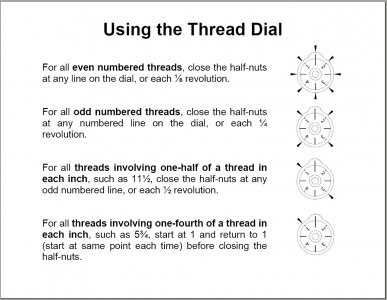

From "How to run a lathe", 1935 edition:

I've looked all through the book and can't find "shipper-rod" identified anywhere. Is there a way to reverse the carriage travel without getting out of synch, other than stopping and reversing the motor? Since I converted to a 3-phase motor on a VFD, my lathe doesn't start and stop quickly.

I'm just learning to cut threads, so if anyone has links to a how-to that is applicable for my 1937 model T 11" SBL, I would appreciate a pointer. I've searched the usual forums and haven't found anything yet.

Thanks.

I've looked all through the book and can't find "shipper-rod" identified anywhere. Is there a way to reverse the carriage travel without getting out of synch, other than stopping and reversing the motor? Since I converted to a 3-phase motor on a VFD, my lathe doesn't start and stop quickly.

I'm just learning to cut threads, so if anyone has links to a how-to that is applicable for my 1937 model T 11" SBL, I would appreciate a pointer. I've searched the usual forums and haven't found anything yet.

Thanks.