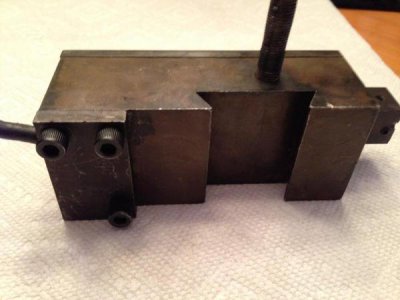

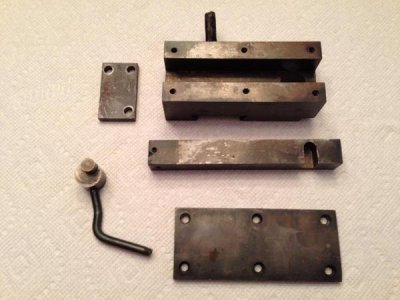

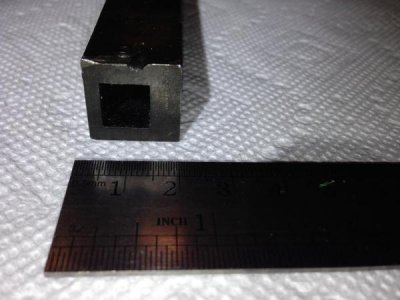

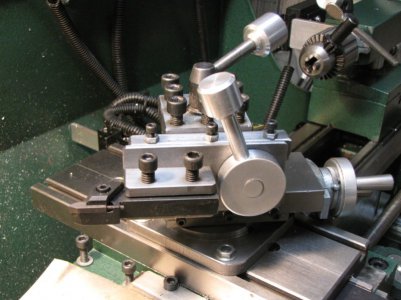

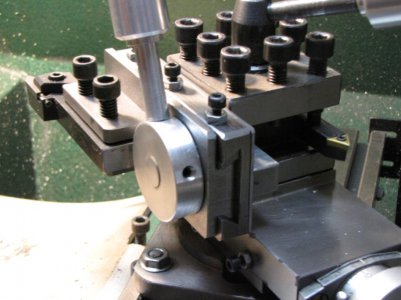

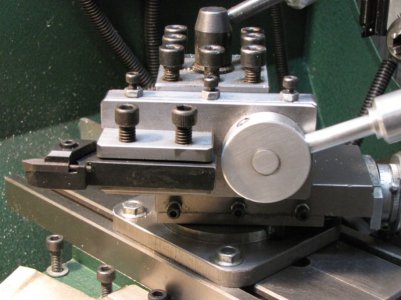

Well, after questions and ordering some dove tail cutters etc. I finally got this holder put together. Not that there wasn't a few issues with the making of the tool. Had to work really slow with the dove tails as was suggested to make sure I didn't destroy the cutters, as I also only have a Grizzly G8689 mini mill and that worked out well. I did try to figure out the math for cutting these but didn't seem to work for me so just used a caliper and 6in rule . Had to make 2 cams because of a miscalculation but that also finally worked out. Funny how on paper things seem to be fine till you start building and find either a better way or a better idea. On one cam I set up the cam in the wrong direction in the 4 jaw chuck so learned again from that mistake. Anyway in the end it has turned out and that's all that counts. I do have a lot of time in on it but this is a Hobby right.!!! I kind of copied the idea but with my own ideas as I didn't like the large size of the ones I seen so just put my own tweast on it.

Well after questions and ordering some dove tail cutters etc. I finally got this holder put together. Not that there wasn't a few issues with the making of the tool. Had to work really slow with the dove tails as was suggested to make sure I didn't destroy the cutters, as I also only have a Grizzly G8689 mini mill and that worked out well. I did try to figure out the math for cutting these but didn't seem to work for me so just used a caliper and 6in rule . Had to make 2 cams because of a miscalculation but that also finally worked out. Funny how on paper things seem to be fine till you start building and find either a better way or a better idea. On one cam I set up the cam in the wrong direction in the 4 jaw chuck so learned again from that mistake. Anyway in the end it has turned out and that's all that counts. I do have a lot of time in on it but this is a Hobby right.!!! I kind of copied the idea but with my own ideas as I didn't like the large size of the ones I seen so just put my own tweast on it.

Well after questions and ordering some dove tail cutters etc. I finally got this holder put together. Not that there wasn't a few issues with the making of the tool. Had to work really slow with the dove tails as was suggested to make sure I didn't destroy the cutters, as I also only have a Grizzly G8689 mini mill and that worked out well. I did try to figure out the math for cutting these but didn't seem to work for me so just used a caliper and 6in rule . Had to make 2 cams because of a miscalculation but that also finally worked out. Funny how on paper things seem to be fine till you start building and find either a better way or a better idea. On one cam I set up the cam in the wrong direction in the 4 jaw chuck so learned again from that mistake. Anyway in the end it has turned out and that's all that counts. I do have a lot of time in on it but this is a Hobby right.!!! I kind of copied the idea but with my own ideas as I didn't like the large size of the ones I seen so just put my own tweast on it.