So I'm working on a haul the likes of which I have never seen, I will have pictures of everything starting Friday and proceeding onward after I get all this equipment home and have a chance to sort though it all...

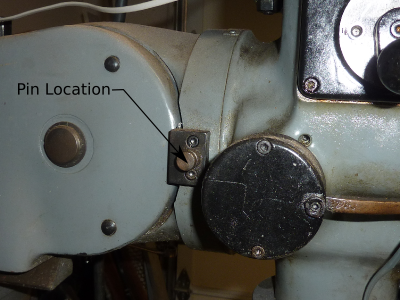

That having been said, I'm attaching a picture of a bridgeport head that was provided by the current owner as it's all I have at the moment. It's a complete machine but hasn't been used in years.

First things first, are there any good definitive guides or how to's on how to move one of these things? And second, can anyone identify this machine or even just the head type based on just the one terrible picture and possibly point me in the direction of some resources on it? It'd be greatly appreciated.

Thanks all!

That having been said, I'm attaching a picture of a bridgeport head that was provided by the current owner as it's all I have at the moment. It's a complete machine but hasn't been used in years.

First things first, are there any good definitive guides or how to's on how to move one of these things? And second, can anyone identify this machine or even just the head type based on just the one terrible picture and possibly point me in the direction of some resources on it? It'd be greatly appreciated.

Thanks all!