Hi all,

I've been keeping my eye out for a deal on a bog standard rotary table, and I recently scored an obsolete CNC rotary at auction. It needs a little elbow grease before I can use it so I'm seeking a little advice It was described as a "Boston gear Series 300 gear reducer with attached table".

It was described as a "Boston gear Series 300 gear reducer with attached table".

This is what the thing looked like (think robot octopus):

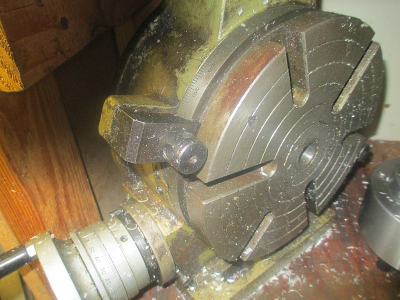

Pretty sure my friend, who picked the 300lb mess up for me, now hates me... Anyway, after some finagling to get it home, and several hours of disassembly, here's what I have:

1) 10-1/2" rotary table (very useful, but needs a couple of things)

2) 11" x 6" x 1.5" angle plate (very useful)

3) 12" x 12" x 2" (heavy!) flat fixture plate (I'm sure I'll find a use for it)

4) Boston gear Series 300 right-angle gear reducer (useful. Will go in my bandsaw for metal cutting conversion)

5) Fanuc motor, specs unknown (nameplate unreadable, not likely useful)

6) Fanuc control circuitry (obsolete model)

7) Di-Acro short stroke air cylinder (?)

8) a bunch of hydraulic fittings (?)

9) a tangled mess of electrical wire in flex conduit and air/hydraulic hose (probably useful somewhere down the line)

10) about a million cap head screws, and a bunch of miscellaneous brackets, fittings and widgets (?)

So, aside from the tonnes of grease and filth, I'm pretty pleased so far... The angle plate and fixture plate are always good to have, and the gear reducer is an added bonus. The rotary table seems fairly tight, and the table doesn't have much wear (the scraping is still visible). It does need 2 things, though (the belated point of this thread):

1) a handwheel (no need for that on a CNC machine, I guess!)

2) table locks/clamps (I guess the air cylinder was some sort of brake, but not usable for my purposes)

So, the questions (finally!):

1) is there anything special about a handwheel for a rotary table, or can I just adapt any wheel-shaped object I have around? The arcminutes dial is present, and I don't think I would ever do anything requiring arcsecond accuracy

2) if adapting a handwheel, would it be better to put it on the shaft with the dial (which has no provision for attaching a handwheel) or on the auxiliary input shaft oncthe other side? I'm thinking the dial-side, although it will need some sort of adapter...

3) not sure where to start with making table locks - I don't see anything else that resembles that on the table. Any suggestions for how to go about that?

Thanks in advance!

Lee

Sent from my SM-N920T using Tapatalk

I've been keeping my eye out for a deal on a bog standard rotary table, and I recently scored an obsolete CNC rotary at auction. It needs a little elbow grease before I can use it so I'm seeking a little advice

This is what the thing looked like (think robot octopus):

Pretty sure my friend, who picked the 300lb mess up for me, now hates me... Anyway, after some finagling to get it home, and several hours of disassembly, here's what I have:

1) 10-1/2" rotary table (very useful, but needs a couple of things)

2) 11" x 6" x 1.5" angle plate (very useful)

3) 12" x 12" x 2" (heavy!) flat fixture plate (I'm sure I'll find a use for it)

4) Boston gear Series 300 right-angle gear reducer (useful. Will go in my bandsaw for metal cutting conversion)

5) Fanuc motor, specs unknown (nameplate unreadable, not likely useful)

6) Fanuc control circuitry (obsolete model)

7) Di-Acro short stroke air cylinder (?)

8) a bunch of hydraulic fittings (?)

9) a tangled mess of electrical wire in flex conduit and air/hydraulic hose (probably useful somewhere down the line)

10) about a million cap head screws, and a bunch of miscellaneous brackets, fittings and widgets (?)

So, aside from the tonnes of grease and filth, I'm pretty pleased so far... The angle plate and fixture plate are always good to have, and the gear reducer is an added bonus. The rotary table seems fairly tight, and the table doesn't have much wear (the scraping is still visible). It does need 2 things, though (the belated point of this thread):

1) a handwheel (no need for that on a CNC machine, I guess!)

2) table locks/clamps (I guess the air cylinder was some sort of brake, but not usable for my purposes)

So, the questions (finally!):

1) is there anything special about a handwheel for a rotary table, or can I just adapt any wheel-shaped object I have around? The arcminutes dial is present, and I don't think I would ever do anything requiring arcsecond accuracy

2) if adapting a handwheel, would it be better to put it on the shaft with the dial (which has no provision for attaching a handwheel) or on the auxiliary input shaft oncthe other side? I'm thinking the dial-side, although it will need some sort of adapter...

3) not sure where to start with making table locks - I don't see anything else that resembles that on the table. Any suggestions for how to go about that?

Thanks in advance!

Lee

Sent from my SM-N920T using Tapatalk