-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Repairs And Upgrades On My Burke #4

- Thread starter Mark_f

- Start date

The steel plate I made to hold my vertical head , while it does function, has its drawbacks and problems. I would greatly appreciate if anyone out there that has one could make a drawing with dimensions for this plate to hold the vertical head. I am going to have to make one as I have been unable to locate one.( they are as scarce as unicorn crap). A fellow I helped once said he had that plate he got in a box of stuff at an auction. He didn't know what it was . He was supposed to bring it to me but .... He didn't show up. I am tired of fighting this piece of steel. I have to bite the bullet and make one.

- Joined

- Nov 14, 2014

- Messages

- 851

Mark, I have a vertical head that came with the Burke I am restoring. Haven't used it yet, but will look tomorrow and see if it is complete with mounting bracket. If so, I can try to lift some dimensions and send you a drawing of what ever I might have... Actually don't remember what the mounting bracket looks like - as the Burke isn't fully reassembled yet, and some parts are all in a box.

Glenn

Glenn

I would really appreciate that. It is an easy part to spot. I know it is cast iron, about 10" long , has a slot for 90 degrees. The distance between the top and bottom hole is important. I'm going to have to bite the bullet and buy a really expensive hunk of cast iron to make one and I sure don't want to make a mistake. That hunk of iron is close to $100.

- Joined

- Dec 15, 2011

- Messages

- 191

Mark,

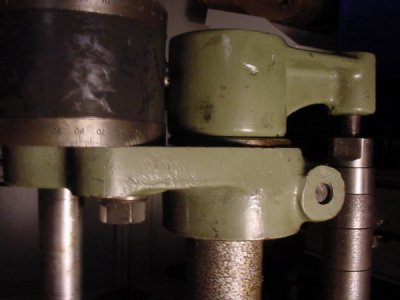

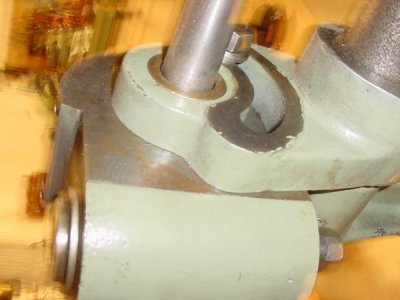

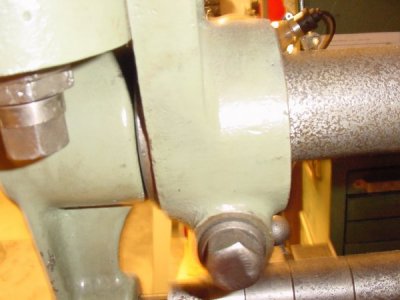

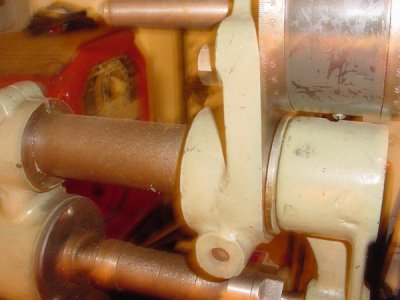

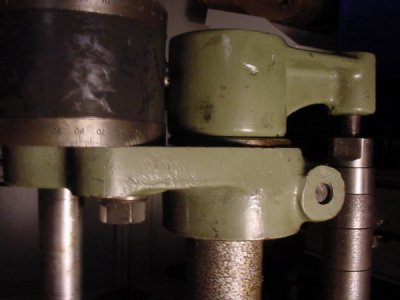

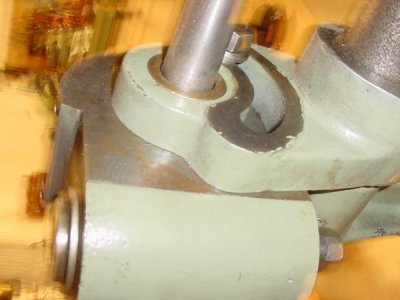

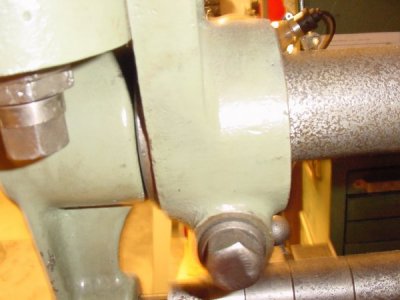

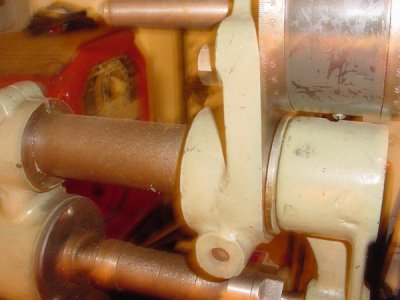

Here are some photos of my vertical head on my Burke #4 The plate you made is spot on the only difference would be added weight as the original factory mount is a casting and the split bushing with eccentric offset is 2.375 Dia. the hole for the shaft of the head is 1.655 at the bushing. the unit is 8 " OAL and the width is 4.5 " at the top and tapers down to 3.625" at the bolt to secure it.

The size of the overarm is 2 " dia as you are already aware. I'll try to get a drawing posted but it will only be a sketch to give you a general idea of its shapes.If I can be of any further assistance let me know glad to help.

Regards

dgehricke

Here are some photos of my vertical head on my Burke #4 The plate you made is spot on the only difference would be added weight as the original factory mount is a casting and the split bushing with eccentric offset is 2.375 Dia. the hole for the shaft of the head is 1.655 at the bushing. the unit is 8 " OAL and the width is 4.5 " at the top and tapers down to 3.625" at the bolt to secure it.

The size of the overarm is 2 " dia as you are already aware. I'll try to get a drawing posted but it will only be a sketch to give you a general idea of its shapes.If I can be of any further assistance let me know glad to help.

Regards

dgehricke

Yea, but it will cut easy. I figure a block 1 1/2" thick and 9" long will do the trick. It runs right at $100 delivered. Yes, a bit of work but I got everything fixed up on this mill and this is the last piece. I made new screws and nuts for the knee and y axis. I am going to make a new nut for the table. This mill will be better than when it was new.Mark,

That is a lot of swarf and cast iron WOW.

Good Luck if you need anything else that I can be of help holler at me.

Regards

dgehricke

Mark ... that darn fellow with the bad memory sure feels bad for completely letting that slip from his mind until he found this thread .

And your right I didn't know how important that piece is . I have it somewhere still .. along with an arbor that I'm pretty sure is either bent or has a messed up taper .

I'll be away from the house untill Saturday morning .. but I just put a large reminder on my refrigerator . Soon as I get back home it will be my first priority to find it

And your right I didn't know how important that piece is . I have it somewhere still .. along with an arbor that I'm pretty sure is either bent or has a messed up taper .

I'll be away from the house untill Saturday morning .. but I just put a large reminder on my refrigerator . Soon as I get back home it will be my first priority to find it