- Joined

- Aug 7, 2017

- Messages

- 4

Hello all!

I've been up and down Google searching for the right approach to my project. I've looked at engraving places, vinyl printing, acid etching, 3D printing and a bunch of other solutions.

For the most part they cost a ton which isn't the best option since my hobby is purely for fun.

I build guitar amps out of all sorts of things like ammo cans and random stuff I find in antique stores and while they come out sounding good, they tend to look bad because I have to hand paint the controls onto the unit and I am not particularly good a that.

So it occurred to me that I could design the plate that goes under the knobs much like something you would seen on a Marshal head in a nice brass or other metal depending on the amp body.

Problem is, I have no idea how to get to that finished look. So I'm wondering if anyone has some suggestions about applying a design such as control markings and labels to a metal plate.

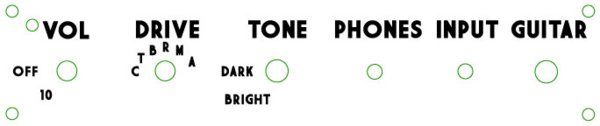

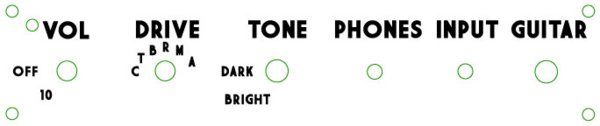

I've attached a simple layout as a conversation point to see if I can get some help. The green are my drill holes which I have learned how to do at home.

Thanks!

I've been up and down Google searching for the right approach to my project. I've looked at engraving places, vinyl printing, acid etching, 3D printing and a bunch of other solutions.

For the most part they cost a ton which isn't the best option since my hobby is purely for fun.

I build guitar amps out of all sorts of things like ammo cans and random stuff I find in antique stores and while they come out sounding good, they tend to look bad because I have to hand paint the controls onto the unit and I am not particularly good a that.

So it occurred to me that I could design the plate that goes under the knobs much like something you would seen on a Marshal head in a nice brass or other metal depending on the amp body.

Problem is, I have no idea how to get to that finished look. So I'm wondering if anyone has some suggestions about applying a design such as control markings and labels to a metal plate.

I've attached a simple layout as a conversation point to see if I can get some help. The green are my drill holes which I have learned how to do at home.

Thanks!