- Joined

- Jun 10, 2017

- Messages

- 5

My convertible top is not opening because a steel strip connected to a microswitch is broken and needs to be replaced. As shown in this image http://imgur.com/Fdgvokz the steel strip below the blue switch is broken.

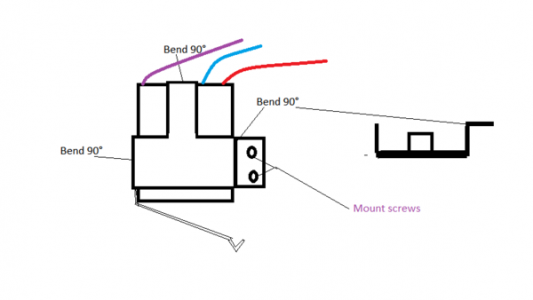

I bought a microswitch and broke it open took it's lever and attached it to the microswitch in my car using jb weld as shown here http://imgur.com/wia2tzt. However in order to attach the lever I had to pull out the microswitch in my car. I now have to reattach the microswitch to the frame. I had two questions:

1. What would be the best way to reattach the microswitch to the frame? I would use jb-weld but I might have to remove the microswitch in case the lever malfunctions again and jb-weld seems to be creating a very strong bond. To remove jb-weld I will have to use heat and any kind of heat or pressure on the microswitch will break the switch(it almost broke when I removed it the first time). I would like to use a glue that is strong but can be removable by some kind of solvent. I even thought of industrial strength velcro since then I can remove the switch and move it around as I pleased.

2. Is there any way to put a clip or so around the lever so that jb-weld doesn't come apart due to pressure when the lever is pressed? The clip will have to be about 2 cm in width and hug that switch as close as possible so that it doesn't fall due to vibration etc.?

I bought a microswitch and broke it open took it's lever and attached it to the microswitch in my car using jb weld as shown here http://imgur.com/wia2tzt. However in order to attach the lever I had to pull out the microswitch in my car. I now have to reattach the microswitch to the frame. I had two questions:

1. What would be the best way to reattach the microswitch to the frame? I would use jb-weld but I might have to remove the microswitch in case the lever malfunctions again and jb-weld seems to be creating a very strong bond. To remove jb-weld I will have to use heat and any kind of heat or pressure on the microswitch will break the switch(it almost broke when I removed it the first time). I would like to use a glue that is strong but can be removable by some kind of solvent. I even thought of industrial strength velcro since then I can remove the switch and move it around as I pleased.

2. Is there any way to put a clip or so around the lever so that jb-weld doesn't come apart due to pressure when the lever is pressed? The clip will have to be about 2 cm in width and hug that switch as close as possible so that it doesn't fall due to vibration etc.?