- Joined

- Jan 16, 2016

- Messages

- 302

I HAT THE GOOD FORTUNATE TO RUN ACROSS A HARDINGE MODEL C RADIUS ATTACHMENT .

THESE THINGS ARE DEAR AND CAN SELL FOR A FEW THOUSAND DOLLARS .

TROUBLE IS , I DON'T HAVE A HARDINGE LATHE . MY LATHE IS A MAXIMAT SUPER 11

NO PROBLEM ! ARE WE TOOLMAKERS OR AREN'T WE ?

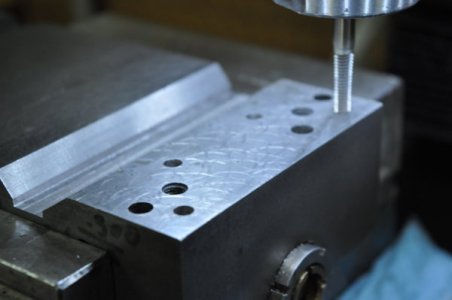

THROUGH CLEVERNESS , DETERMINATION & HARD WORK , I MODIFIED THE

HARDINGE TOOL TO WORK OK THE MAXIMAT LATHE . IT's A DREAM COME TRUE .

NOW THAT I AM MAKING BALLS AND POSTS WITH WEIRD SHAPES , MY

PRECIOUS RADIUS ATTACHMENT IS STARTING TO RUST !

I KEEP IT OILED AND WILE IT DOWN WITH EACH USE BUT IT DRIVES ME NUTS

THAT IT SITS IN A METAL CABINET JUST WAITING TO CONDENSE WATER .

I WANTED A NICE WOODEN BOX TO STORE IT IN THAT KEEPS MOISTURE AWAY .

IT ALSO NEEDED TO FIT IN THE CABINET .

I BOUGHT A HUGE BROWN & SHARPE MAHOGANY HEIGHT GAUGE CASE ON E-BAY .

I DISSECTED IT AND RE-PURPOSED IT TO FIT THE RADIUS TOOL .

IT IS NOW 10" SHORTER AND 3" SMALLER IN HEIGHT WITH LEFT OVER PIECES BEING

USED TO NEST THE ATTACHMENT . BOTH HANDLES COME OFF WHEN NOT IN USE .

THE BOX FITS IN MY CABINET AS NICELY AS THE HARDINGE FITS IN THE BOX .

THESE THINGS ARE DEAR AND CAN SELL FOR A FEW THOUSAND DOLLARS .

TROUBLE IS , I DON'T HAVE A HARDINGE LATHE . MY LATHE IS A MAXIMAT SUPER 11

NO PROBLEM ! ARE WE TOOLMAKERS OR AREN'T WE ?

THROUGH CLEVERNESS , DETERMINATION & HARD WORK , I MODIFIED THE

HARDINGE TOOL TO WORK OK THE MAXIMAT LATHE . IT's A DREAM COME TRUE .

NOW THAT I AM MAKING BALLS AND POSTS WITH WEIRD SHAPES , MY

PRECIOUS RADIUS ATTACHMENT IS STARTING TO RUST !

I KEEP IT OILED AND WILE IT DOWN WITH EACH USE BUT IT DRIVES ME NUTS

THAT IT SITS IN A METAL CABINET JUST WAITING TO CONDENSE WATER .

I WANTED A NICE WOODEN BOX TO STORE IT IN THAT KEEPS MOISTURE AWAY .

IT ALSO NEEDED TO FIT IN THE CABINET .

I BOUGHT A HUGE BROWN & SHARPE MAHOGANY HEIGHT GAUGE CASE ON E-BAY .

I DISSECTED IT AND RE-PURPOSED IT TO FIT THE RADIUS TOOL .

IT IS NOW 10" SHORTER AND 3" SMALLER IN HEIGHT WITH LEFT OVER PIECES BEING

USED TO NEST THE ATTACHMENT . BOTH HANDLES COME OFF WHEN NOT IN USE .

THE BOX FITS IN MY CABINET AS NICELY AS THE HARDINGE FITS IN THE BOX .