- Joined

- Jun 26, 2013

- Messages

- 191

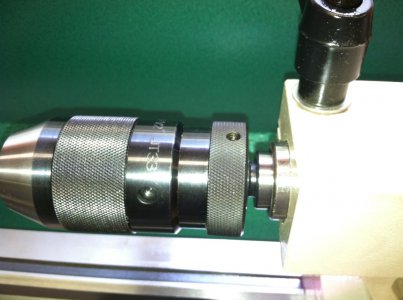

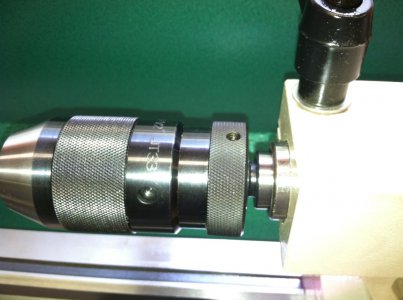

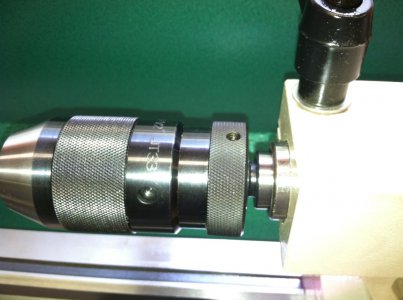

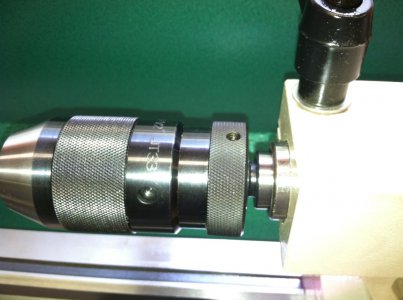

Well, I took the plunge and cut the tang off the chuck taper, that bought me about 3/4". Then I noticed that the ram is easily removed when extended all the way out. I pulled it out and noticed that the taper mating surface ends about 3/8" short of the machined surface on the chuck taper, so there's no way shortening the taper itself will reduce the gripping strength. I measured and decided I could remove a little more than an additional 1/4" from the end of the taper and still 1) engage the entire length of the taper in the ram, 2) pull the ram back all the way to zero without disengaging the taper, and 3) still be long enough to disengage the taper by bringing the ram just a little further back. So I went ahead and cut a little more of the taper off. This is what I ended up with...

I now have full range of motion of the ram. All the way from "fully extended" (about 2.25"):

back to "fully retracted" (0.0"):

Thanks for your thoughts - they helped me decide what approach to take.

--Ralph

I now have full range of motion of the ram. All the way from "fully extended" (about 2.25"):

back to "fully retracted" (0.0"):

Thanks for your thoughts - they helped me decide what approach to take.

--Ralph