- Joined

- Nov 22, 2010

- Messages

- 371

Hey guys,

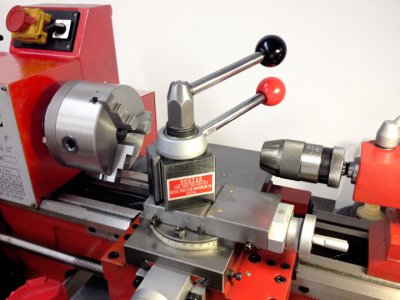

I have decided that I need a QCTP for my 10" Logan 825. I would like an aloris but I will have to win the lottery first.

I have to go with the best price for now and I'm thinking the bostar AXA from CDCO Machinery will be my best bet.

Anyone have experience with the Bostar brand ? I realize that the PHASE II is a reputable china Doll but I am really pinching pennies right now as I have been out of work for six months due to health problem but I am back and I am alive and well just broke for the time being.

any info on Bostar will be appreciated )

)

Joebiplane

I have decided that I need a QCTP for my 10" Logan 825. I would like an aloris but I will have to win the lottery first.

I have to go with the best price for now and I'm thinking the bostar AXA from CDCO Machinery will be my best bet.

Anyone have experience with the Bostar brand ? I realize that the PHASE II is a reputable china Doll but I am really pinching pennies right now as I have been out of work for six months due to health problem but I am back and I am alive and well just broke for the time being.

any info on Bostar will be appreciated

Joebiplane

Last edited: