- Joined

- Apr 12, 2012

- Messages

- 579

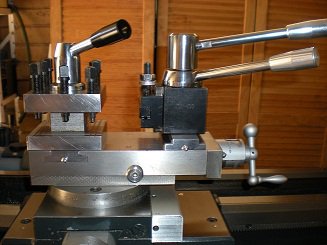

A few months back I decided to switch from an AXA size holder to a BXA holder for my 12x36. I truly hate to reach for a wrench to swivel my tool post, so I make the handle onto the nut.

I start with making the handle to fit the size of the tool post (or the taps on hand etc ;-) ) The size isn't all that critical but needs to be as large as is reasonable. You will be banging it around. Stainless works great if it is on hand but even 1018 is good.

The handle is just gonna be threaded on each end to fit the ball and the nut. Please note the 1018 nut on this AXA QCTP is trying to decide what color to be but worked great.

Next we make the nut itself. It's simple. I like the handle to be longer than the "locking lever" . The nut above has 4 sockets for the handle. If the drilling and tapping is a challenge just go with 1. My handle stays in the same hole always and if it was in the way it could be removed after tightening. If the hole placement was unfortunate and the handle was in the way (pointed to the chuck etc) facing the bottom or adding a washer will make it good.

So now you just make the nut and thread it to fit the T nut bolt like above.

Next use what you have to drill and tap 1 or more holes for the handle. Some of you may have a indexing head with adjustable angle. PHWHATTT we play the cards we are delt and use a rod in the hole to index.

I start with making the handle to fit the size of the tool post (or the taps on hand etc ;-) ) The size isn't all that critical but needs to be as large as is reasonable. You will be banging it around. Stainless works great if it is on hand but even 1018 is good.

The handle is just gonna be threaded on each end to fit the ball and the nut. Please note the 1018 nut on this AXA QCTP is trying to decide what color to be but worked great.

Next we make the nut itself. It's simple. I like the handle to be longer than the "locking lever" . The nut above has 4 sockets for the handle. If the drilling and tapping is a challenge just go with 1. My handle stays in the same hole always and if it was in the way it could be removed after tightening. If the hole placement was unfortunate and the handle was in the way (pointed to the chuck etc) facing the bottom or adding a washer will make it good.

So now you just make the nut and thread it to fit the T nut bolt like above.

Next use what you have to drill and tap 1 or more holes for the handle. Some of you may have a indexing head with adjustable angle. PHWHATTT we play the cards we are delt and use a rod in the hole to index.