- Joined

- Feb 9, 2015

- Messages

- 100

I have had my HF 7x10 mini lathe for 2 1/2 months now. I bought it to produce some small HF Predator engine parts, that do not exist on the face of the earth. (I set up a mini machine shop in one end of my wife`s kitchen, so I did not have to heat my workshop). After adjusting most of the common factory problems with the lathe, I set about making the parts.

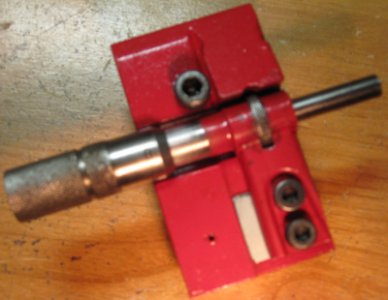

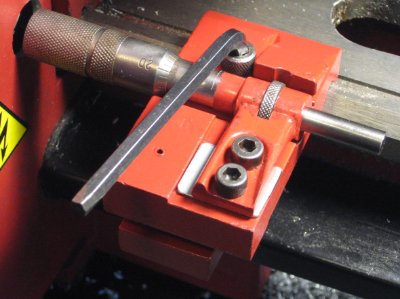

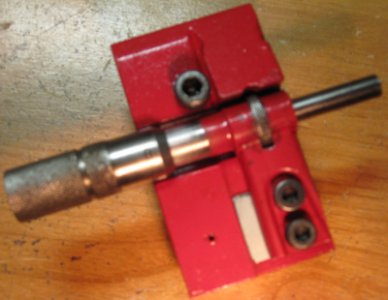

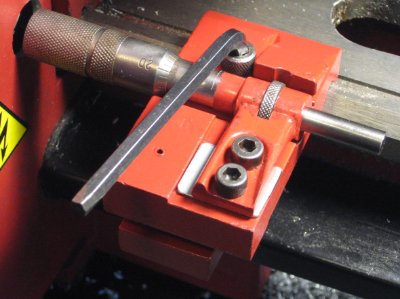

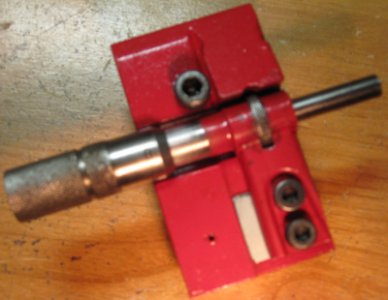

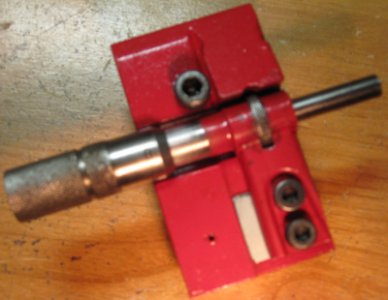

In the process, I got hung up on making some added features to my lathe. An adjustable carriage stop was something I always used, but could not find one for the mini lathes, that I could copy. I had an old and somewhat rusty 6" micrometer where the anvil end had been destroyed. IU cut away most of the frame and removed the ratchet on the thimble, to shorten it up.

I picked up an extra base plate for the tail stock, flipped it around and cut is down. I squared up the remaining part of the micrometer frame, to give me a flat area to work with. Scribed a line on the barrel to give me a reference point for zero and the numbers on the thimble. ---John

Here are some views of the stop itself ---

Top View ---

Bottom View ---

Readings ---

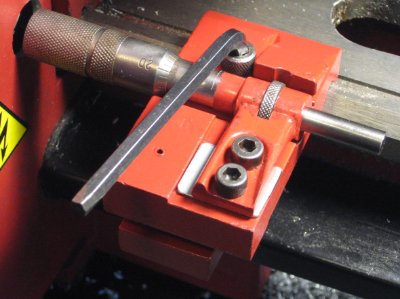

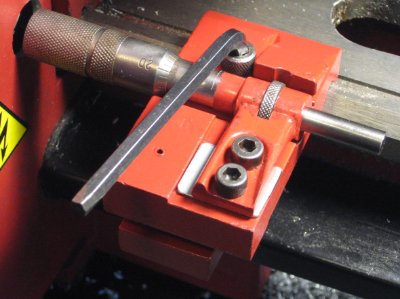

On The Lathe ---

These are the small parts that I am making, and now selling the assembly on E-bay. I used a standard metric hex bolt and a #8 Allen machine screw. ---

Installed on a carburetor, in place of the bolt that holds the bowl on.---

In addition, I am making this oil drain plug adaptor. I make it in both 10mm and 12mm male threads. The other end is a 1/4 pipe thread. They are to extend the oil drain hole on the import engines, with any length pipe nipple you require.

In the process, I got hung up on making some added features to my lathe. An adjustable carriage stop was something I always used, but could not find one for the mini lathes, that I could copy. I had an old and somewhat rusty 6" micrometer where the anvil end had been destroyed. IU cut away most of the frame and removed the ratchet on the thimble, to shorten it up.

I picked up an extra base plate for the tail stock, flipped it around and cut is down. I squared up the remaining part of the micrometer frame, to give me a flat area to work with. Scribed a line on the barrel to give me a reference point for zero and the numbers on the thimble. ---John

Here are some views of the stop itself ---

Top View ---

Bottom View ---

Readings ---

On The Lathe ---

These are the small parts that I am making, and now selling the assembly on E-bay. I used a standard metric hex bolt and a #8 Allen machine screw. ---

Installed on a carburetor, in place of the bolt that holds the bowl on.---

In addition, I am making this oil drain plug adaptor. I make it in both 10mm and 12mm male threads. The other end is a 1/4 pipe thread. They are to extend the oil drain hole on the import engines, with any length pipe nipple you require.